TL;DR:

- SymphonyAI introduces a cutting-edge Industrial Large Language Model (LLM).

- Trained on a vast industrial dataset, it accelerates operational efficiency and decision-making.

- Hosted on Microsoft Azure, it connects and contextualizes manufacturing data.

- The LLM adapts in real-time to changing operational variables.

- Democratizes access to domain knowledge, benefiting both experts and novices.

- Prateek Kathpal, CEO of SymphonyAI Industrial, foresees a transformative era in intelligent manufacturing.

- Initially available for private preview, developers can leverage the Industrial LLM API.

- Microsoft Teams AI Library and Azure Machine Learning Studio will host the model.

- It serves as a valuable learning tool for educational institutions.

Main AI News:

In a groundbreaking move, SymphonyAI, a pioneer in predictive and generative enterprise AI SaaS, has introduced one of the world’s foremost industrial large language models (LLM), poised to revolutionize large-scale industrial transformation. This Industrial LLM represents a paradigm shift, and its potential impact on the manufacturing sector cannot be overstated.

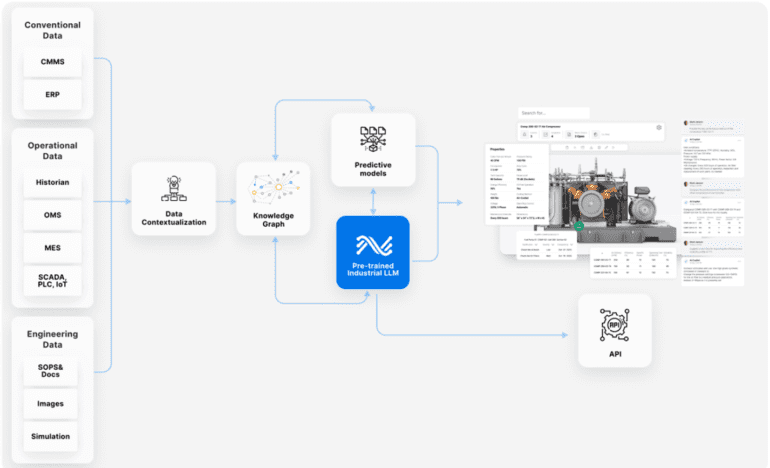

This Industrial LLM, a product of SymphonyAI’s relentless innovation, is the result of intensive training on a staggering 1.2 billion tokens, leveraging one of the largest industrial datasets worldwide. Comprising an impressive 3 trillion data points, over 500,000 machine tests, 150,000 components, and 80,000 diverse assets, this model is engineered to empower industrial enterprises with the prowess of predictive and generative AI. Its core mission is to enhance operational efficiency, productivity, and margins by furnishing operators with contextually enriched insights, enabling swift, informed decision-making. Notably, this LLM accelerates the delivery of context-aware data, ensuring operators access critical knowledge up to 90% faster than conventional systems.

Deployed on the robust Microsoft Azure platform, the Industrial LLM seamlessly integrates and contextualizes manufacturing data across the spectrum, spanning from individual assets to global multi-plant operations. It serves as a self-contained intelligence hub for addressing asset performance and reliability queries. Alternatively, it can be seamlessly integrated into downstream systems and plant data sources. Regardless of the mode, it delivers real-time, quantifiable business outcomes while nurturing the growth of industrial knowledge, fostering a more interconnected workforce. With its adaptability to incoming data and real-time actions, the Industrial LLM remains agile in keeping pace with ever-changing operational variables.

Perhaps most importantly, the Industrial LLM democratizes knowledge within the industrial landscape. By placing meaningful context-aware data at the fingertips of operators and plant managers, it empowers even novice users to tap into years of domain expertise, swiftly surmounting complex challenges.

Indranil Sircar, CTO of Manufacturing at Microsoft, commented on this transformative development: “Bringing Industrial LLM to the industrial market is a significant advancement for the industry. SymphonyAI’s approach of combining the precision of industrial domain knowledge with the power of generative AI will enable manufacturers to tap into the expertise of the operator or technician and unlock never-before-seen value from their data.”

In a sector often characterized by fragmented point solutions, the SymphonyAI Industrial LLM stands as a game-changer, laying the foundation for a new era of industrial applications and computational processes. It pushes the boundaries of physics while fundamentally reshaping how plant managers, operators, reliability engineers, and quality analysts glean insights from data and execute essential tasks.

Prateek Kathpal, President and CEO of SymphonyAI Industrial, emphasized the transformative potential of this innovation: “We are launching a new era of intelligent manufacturing, tapping into the depth of our product portfolio and our extensive history and visibility across domains and datasets, including both machine and non-machine datasets. The Industrial LLM is trained with our world-class industrial datasets to provide essential groundwork for digital manufacturing innovators to unleash transformative AI solutions for their customers.”

This Industrial LLM is a trailblazer, representing one of the world’s first industrial domain-grounded LLMs. It has been meticulously trained on vast proprietary industrial datasets and a curated knowledge base to perform specific tasks tailored for industrial users. These tasks encompass machine condition diagnostics, prescriptive recommendations, answering queries on fault conditions, test procedures, maintenance protocols, manufacturing processes, and industrial standards.

While the Industrial LLM is initially available for private preview, developers are encouraged to harness its potential by building their own robust custom industrial applications through the Industrial LLM API. Additionally, it will be accessible in the Microsoft Teams AI Library and as a model in the Model Catalog in the Azure Machine Learning Studio. Furthermore, it serves as an invaluable learning resource for universities and colleges training the next generation of intelligent manufacturing talent.

Conclusion:

SymphonyAI’s introduction of the Industrial LLM marks a significant milestone in the evolution of smart manufacturing. This innovative model is poised to bridge the gap between data and actionable insights, promising to unlock unprecedented value for the industry. Its democratization of knowledge and adaptability to changing circumstances will empower manufacturers, ultimately reshaping how they derive insights and execute critical tasks. This development heralds a new era of precision, efficiency, and knowledge empowerment within the market.