TL;DR:

- 1000 Kelvin’s AI software, AMAIZE, is now commercially available for 3D printing.

- Partnerships with leading 3D printer manufacturers, including EOS, and collaborations with industry players.

- CEO Omar Fergani emphasizes AMAIZE’s role in reducing carbon emissions and energy usage in manufacturing.

- AMAIZE streamlines 3D printing with physics-informed AI, reducing material and energy waste.

- Integration with machine OEMs and early adoption across energy, aerospace, and manufacturing sectors.

- Success story: 80% reduction in support structures, 30% cost reduction in a critical part for a rocket launch provider.

- 1000 Kelvin secures $3 million in funding and expands to Los Angeles.

Main AI News:

In a groundbreaking move set to reshape the landscape of 3D printing technology, 1000 Kelvin, the Berlin/Los Angeles-based startup, has officially unveiled its AI-driven software, AMAIZE, at Formnext 2023. This pivotal moment marks the full commercial availability of a cutting-edge solution that promises to redefine the way we approach metal and polymer 3D printing.

As part of this momentous occasion, 1000 Kelvin proudly announces its strategic partnerships with leading 3D printer manufacturers, including the industry giant EOS, and its collaboration with forward-thinking customers, such as a prominent California-based rocket launch provider. The synergy between these innovative minds and AMAIZE’s transformative capabilities signifies a significant step forward in the evolution of 3D printing technology.

“The manufacturing and production sector,” asserts Omar Fergani, Ph.D., Co-founder and CEO of 1000 Kelvin, “accounts for one-fifth of global carbon emissions and 54% of the world’s energy usage. 3D printing has the unique ability to address these issues, but not until it works consistently. By improving the efficiency and reducing the waste associated with 3D printing, while making the technology easier to use, AMAIZE contributes to a more sustainable future.”

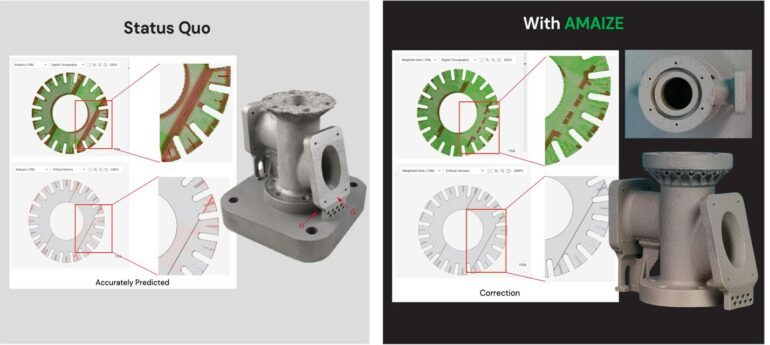

At the heart of this groundbreaking solution is AMAIZE’s capacity to generate optimal print recipes through its physics-informed AI technology, facilitating first-time-right 3D printing. The process is seamless—users simply upload their print file to the AMAIZE cloud, which conducts an in-depth analysis of the part and subsequently corrects thermo-mechanical issues by optimizing the scan strategy and process parameters. This innovation eliminates the need for costly finite element simulation software and the time-consuming process of multiple physical iterations, thereby reducing the consumption of materials, energy, and financial resources.

1000 Kelvin’s commitment to pioneering solutions extends to its integration of AMAIZE with multiple machine OEMs, setting the stage for next-generation AI software and compute infrastructure for additive manufacturing. Through its early adoption program, AMAIZE has already found a welcome home in companies across diverse industries, including energy, aerospace, and contract manufacturing.

One notable success story involves a California-based rocket launch provider that encountered formidable challenges in 3D printing a critical component. The root of the problem lay in print failure due to overheating and the substantial reduction of support structures, leading to operational inefficiencies and costly delays.

AMAIZE came to the rescue by facilitating digital iterations to address these thermal management issues. The outcome was a perfectly printed component, boasting improved surface quality and enhanced performance. Most impressively, AMAIZE empowered the customer to reduce support structures by an astounding 80%, resulting in a remarkable 30% reduction in the overall cost per part when considering both saved materials and post-processing expenses. This case study stands as a testament to AMAIZE’s unwavering commitment to addressing the core issue of thermal management, ultimately accelerating time-to-market for its users.

With a solid foundation of $3 million in funding, 1000 Kelvin has embarked on a journey that transcends geographical boundaries. Its presence now extends to Los Angeles, California, where it is fully poised to cater to the discerning needs of clients in the aerospace and defense industry.

Conclusion:

AMAIZE’s commercial availability and partnerships signal a transformative shift in the 3D printing market. Its AI-driven precision, reduced waste, and cost-saving capabilities are poised to revolutionize manufacturing processes, making them more sustainable and efficient. This innovation positions 1000 Kelvin as a key player in shaping the future of additive manufacturing.