TL;DR:

- Network Rail is using AI software to locate and remove forgotten scrap materials from railway lines.

- The technology incorporates video and AI capabilities to identify reusable or recyclable materials.

- Removing scrap materials reduces the risk of injuries and enhances the overall appearance of the railway.

- Automated Intelligent Video Review (AIVR) captures high-definition video footage for analysis.

- The Wessex route is chosen for the trial due to its high traffic volume.

- The results of the trial will determine the wider implementation of the technology.

- The use of AI technology improves efficiency, safety, and financial savings for Network Rail.

- Scrap materials obstruct engineering work and can be reused or recycled.

- The partnership with One Big Circle enables the accurate location of scrap materials.

- The project aligns with Network Rail’s goal of reusing and recycling materials to save costs.

Main AI News:

In a groundbreaking initiative, Network Rail is leveraging the power of Artificial Intelligence (AI) software to pinpoint forgotten scrap materials alongside railway lines, facilitating their swift and safe removal. This cutting-edge technology, developed in partnership with One Big Circle, incorporates advanced video and AI capabilities to identify old railway resources that can be repurposed or recycled.

By efficiently extracting these materials from the vicinity of railway tracks, the risk of slips, trips, and falls among Network Rail’s workforce is significantly reduced, resulting in a safer working environment. Furthermore, the removal of scrap materials contributes to a more aesthetically pleasing railway infrastructure.

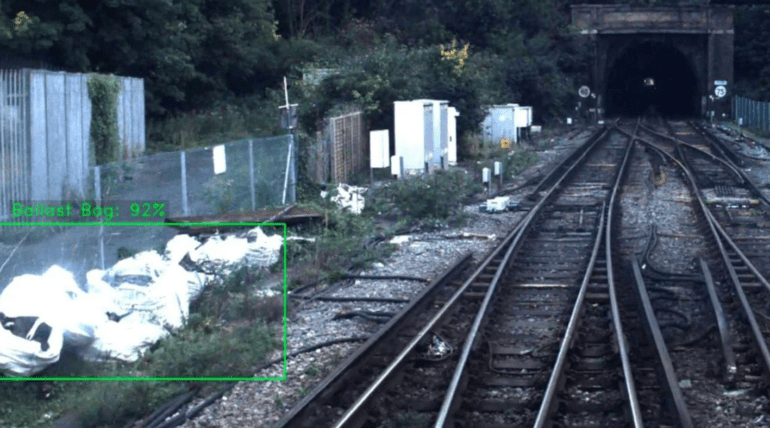

Within Network Rail’s Wessex route, slips, trips, and falls, attributed largely to the presence of scrap materials, account for the majority of workplace injuries. This hazard is particularly pronounced given that a significant portion of maintenance work occurs during nighttime. To address this issue, the organization has adopted Automated Intelligent Video Review (AIVR), a state-of-the-art technology that captures high-definition video footage from a train’s perspective across the rail network. The footage is then uploaded to the cloud, enabling instant access. Utilizing AI algorithms, the system analyzes the video to identify scrap rail, sleepers, and bags of ballast, subsequently mapping their precise locations using GPS coordinates. This valuable information empowers maintenance teams to strategize the safe and timely removal of these items.

The Wessex route has been selected as the testing ground for this trial due to its status as one of the busiest segments of the rail network. The results obtained from this initiative will dictate whether the technology is deployed on a larger scale. Aside from enhancing operational efficiency, the widespread implementation of this technology is expected to yield improvements in safety and generate substantial financial savings.

Wayne Cherry, Network Rail’s Senior Innovations Engineer, recognizes the immense potential of AIVR and its ability to revolutionize the organization’s efficiency. Although AIVR is already utilized in other areas of Network Rail’s operations, this trial marks the first integration of AI in such a capacity, signifying a groundbreaking development in the field.

Cherry emphasizes that aside from being visually displeasing, scrap materials pose various challenges, including obstructing planned engineering work, impeding safe pathways, and causing delays in accessing railway infrastructure for repair purposes during disruptions. With the introduction of safer and more efficient processes for identifying and removing scrap material, Network Rail can safeguard the well-being of its employees while benefiting the broader rail industry, passengers, and taxpayers.

Taking charge of this project, Martyn Shaftoe, Network Rail’s Wessex Route Health and Safety Advisor, expresses enthusiasm for the collaboration with One Big Circle. He believes that this innovative technology will play a vital role in ensuring the safety of frontline workers, enhancing the organization’s efficiency in detecting and removing scrap materials, and ultimately improving the overall condition of the railway for the benefit of passengers and local residents.

In recent years, the railway has unfortunately become a dumping ground for discarded railway sleepers, scrap rail, redundant ballast bags, and other assets. The lack of a definitive inventory of these materials or assets poses a significant challenge. The prospect of employing high-definition video footage and AI to accurately locate scrap materials without requiring staff to traverse the railway is a remarkable safety enhancement.

Shaftoe further highlights the financial benefits of recycling some of the scrap material, with any revenue generated supporting railway operations. Additionally, certain leftover materials can be reused, such as the highly sought-after Bomac concrete sleepers, which are no longer manufactured but remain in demand as replacements on sidings and selected track stretches. Thanks to this groundbreaking technology, 40 of these sleepers have been identified on a site between Yeovil and Weymouth, where they can be recovered and stored for future use across the organization. This approach mitigates the need to purchase costly new equivalents.

The opportunity to assist the industry in saving money through the reuse or recycling of this abundant supply of scrap materials is an exciting prospect. Network Rail aims to expand the implementation of this technology extensively throughout the business later this year.

Emily Kent, Co-founder and Director of One Big Circle, expresses her excitement about this application of AI, developed in close collaboration with Network Rail experts. The AIVR system facilitates the collection of high-quality imagery from railway lines nationwide, enabling engineers and specialists from various disciplines to assess sites remotely. By incorporating automatic detection and location capabilities for scrap rail and other lineside hazards, the system provides the ability to focus on specific issues and respond promptly and safely.

Conclusion:

The implementation of AI technology by Network Rail to streamline the detection and removal of scrap materials represents a significant advancement in the railway industry. By utilizing advanced video and AI capabilities, Network Rail can efficiently locate and remove these materials, reducing the risk of accidents and improving the overall appearance of the railway. This innovative approach not only enhances safety and operational efficiency but also highlights the organization’s commitment to leveraging cutting-edge technologies for the benefit of the rail market. The successful trial and potential wider implementation of this technology signify a transformative change in the way the industry addresses scrap material management, ultimately leading to improved safety, cost savings, and environmental sustainability.