TL;DR:

- BMW utilizes artificial intelligence at its Spartanburg factory to optimize production efficiency.

- AI-powered robots in the body shop ensure precise placement of metal studs on SUV frames.

- An automated inspection system detects and rectifies misplaced studs, reducing the need for human intervention.

- The AI implementation saves BMW over $1 million annually and allows for workforce reallocation.

- 26 cameras on the production line analyze vehicle images to identify and address any issues promptly.

- Factory scanner devices create a digital twin of the facility, enabling virtual testing of production changes.

- This strategic integration of AI enhances productivity, quality, and agility in the manufacturing process.

Main AI News:

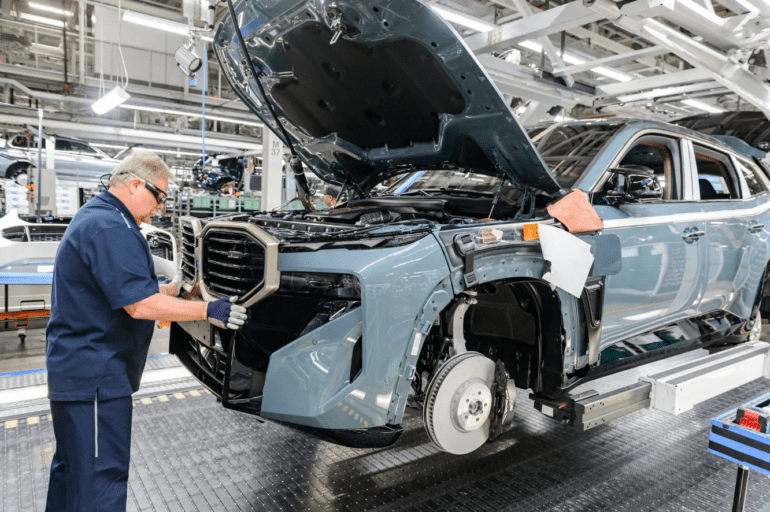

In a bold move towards innovation and efficiency, BMW has harnessed the power of artificial intelligence (AI) to streamline production processes and cut costs at its expansive Spartanburg factory in South Carolina. The renowned German car manufacturer has been making strategic upgrades to incorporate AI functionality within the facility, yielding impressive results.

One area where AI has made a significant impact is in the body shop, where robots are responsible for precision welding, attaching 300 to 400 metal studs to each SUV that comes off the assembly line. Now, these vital components are meticulously inspected and validated by AI, ensuring their precise placement. This automated inspection system not only guarantees top-notch quality but also saves time and resources. Whenever AI detects a misplacement, it swiftly communicates with the robot, prompting immediate adjustments. As a result, the need for six workers on the assembly line has been eliminated, and they have been seamlessly redeployed to more strategic roles. This strategic implementation has translated into substantial savings of over $1 million annually.

Curtis Tingle, BMW Group Manager, lauds the transformative power of this AI-driven approach, stating, “It’s a fully closed loop. [AI] removes human thinking, the human manual intervention, directly out of the equation. We’re achieving five times what we thought was even possible before, with what the AI is achieving now.”

Beyond the body shop, BMW has also integrated AI into its inspection process. Ingeniously, 26 cameras positioned on the production line floor capture detailed images of the vehicles as they progress along the assembly line. These images undergo sophisticated AI analysis, allowing the system to promptly identify any issues or discrepancies that require human attention. This seamless collaboration between AI and human workers optimizes the production flow and ensures uncompromising quality.

Moreover, BMW’s workforce at the Spartanburg plant dons cutting-edge factory scanner devices, capable of capturing precise measurements and images of every aspect of the facility. These images are then utilized to create a digital twin of the factory, where BMW can virtually test and optimize production processes before implementing any changes in the real-world setting. This foresight-driven approach significantly reduces lead times, as the scanning process now takes mere days instead of protracted months.

Conclusion:

BMW’s successful incorporation of artificial intelligence at its Spartanburg plant demonstrates a trailblazing approach to manufacturing. By harnessing AI’s potential, BMW has significantly optimized production efficiency and quality while cutting costs. The elimination of manual intervention and real-time error detection result in substantial savings and the ability to reallocate human resources strategically. This technological leap sets BMW apart as an industry leader, paving the way for others to follow suit in embracing intelligent automation to stay competitive and thrive in the dynamic market landscape.