TL;DR:

- Max-Planck-Institut für Eisenforschung (MPIE) scientists create a machine learning model.

- Model boosts corrosion behavior prediction accuracy by 15% and optimizes alloy formulations.

- Fusion of numerical and textual data enables envisioning of realistic corrosion-resistant alloy compositions.

- Model initially targeted pitting corrosion in high-strength alloys, with potential for broader applications.

- Language processing combined with machine learning for numerical data creates a holistic framework.

- Automated natural language processing identifies enhanced alloy compositions against corrosion.

- Deep-learning model recognizes critical alloy compositions even without initial elemental data.

- Research team integrates textual descriptors and aims to automate data mining.

- Inclusion of microscopy images heralds a future of AI frameworks merging diverse data modalities.

Main AI News:

In a significant stride towards groundbreaking advancements in material science, researchers at the Max-Planck-Institut für Eisenforschung (MPIE) have unveiled a cutting-edge machine learning model. This remarkable creation stands to augment the predictive accuracy of corrosion behavior and potential optimal alloy formulations by an impressive 15%, effectively outperforming existing frameworks.

Detailed in a prestigious exposé within the pages of Science Advances, the scientists emphasize that this innovation possesses the remarkable capability to “envision” novel yet highly plausible corrosion-resistant alloy compositions. What distinguishes this model’s prowess is its seamless fusion of both numerical and textual data, establishing a holistic understanding of the alloy’s characteristics. While initially tailored to combat the challenges of pitting corrosion in high-strength alloys, this model’s adaptability holds the potential to revolutionize diverse alloy attributes.

Dr. Kasturi Narasimha Sasidhar, the lead author of this pioneering research and former postdoctoral researcher at MPIE, elaborates on the critical facets of this model. “The corrosion resistance of each alloy is underpinned by distinct properties that extend beyond the composition itself, encompassing the intricacies of the manufacturing process. Existing machine learning models have been restricted to harnessing numerical data alone. However, the methodologies governing processing and the valuable insights encapsulated in experimental protocols, often conveyed through textual descriptors, play a pivotal role in comprehending corrosion phenomena,” Dr. Sasidhar articulates in an official statement.

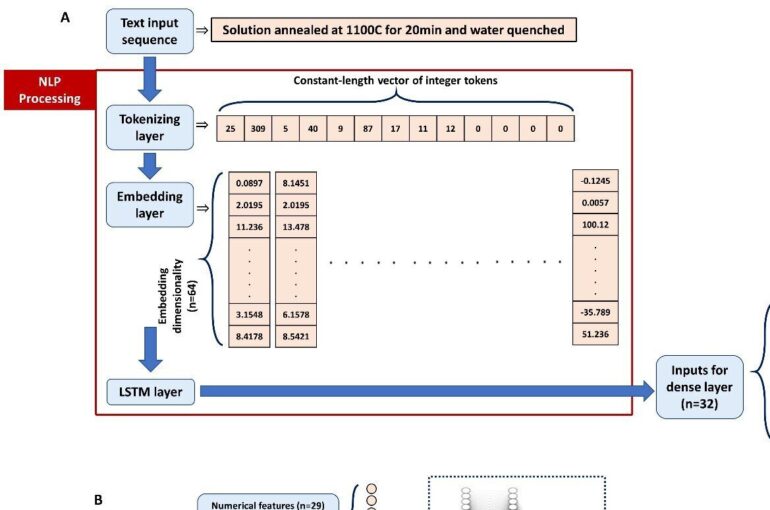

To propel this innovation to fruition, the research team adroitly employed advanced language processing techniques reminiscent of ChatGPT. This linguistic proficiency, when interwoven with state-of-the-art machine learning methodologies for numerical data, culminated in an ingenious natural language processing framework. This architectural marvel seamlessly amalgamates textual data into the machine learning fabric, effectively pinpointing alloy compositions fortified against pitting corrosion.

As Dr. Michael Rohwerder, co-author of the paper, elucidates, “Our deep-learning model underwent rigorous training with intrinsic data, encompassing intricate details of corrosion properties and elemental composition. The model now showcases an unparalleled capacity to discern alloy formulations that stand as bulwarks against corrosion, even in cases where individual elements were not explicitly factored into its initial training.”

The avant-garde framework conceived by Dr. Sasidhar, Dr. Rohwerder, and their accomplished team integrates meticulously curated textual descriptors. Their ongoing mission seeks to automate the data mining process and seamlessly infuse it into the existing framework, thus streamlining the knowledge discovery process.

A notable milestone within this trajectory is the assimilation of microscopy images, heralding a new era of AI frameworks. This visionary approach converges textual, numerical, and image-based data, setting the stage for a comprehensive and multidimensional understanding of alloy properties. The seamless synergy of these diverse data modalities hints at a transformative future for material science innovation, propelling corrosion-resistant alloys into uncharted territories of excellence.

Conclusion:

The groundbreaking AI-driven model developed by MPIE opens new vistas for the material science market. Enhanced predictive accuracy and corrosion-resistant alloy formulations offer industries a competitive edge in producing advanced and resilient materials, transforming the landscape of alloy innovation and application. This convergence of AI and materials science is poised to reshape industry standards, driving efficiency, reliability, and durability across sectors.