TL;DR:

- Researchers from the University of Oxford and Xi’an Jiaotong University have introduced a cutting-edge machine-learning model for simulating phase-change materials (PCMs) in advanced memory technologies.

- This innovative model allows for atomistic simulations of PCMs, providing a deeper understanding of their operation.

- The machine learning-based potential model is trained using quantum-mechanical data and offers exceptional speed and precision.

- The research demonstrates fully atomistic simulations of phase shifts in PCMs, even at the ten-nanometer scale, and can model memory devices with over 500,000 atoms.

- A fresh dataset with labeled quantum mechanical data was used to train the model, showing great promise for atomic-scale PCM-based device simulation.

- ML-driven simulations significantly improve simulation time and accuracy and can be scaled for larger and more complex device geometries.

- The study also highlights the potential for ML-driven simulations to explore interface effects in device engineering, such as the impact of atomic-scale walls on thermal vibrations and phase-transition capabilities.

Main AI News:

In a recent collaborative effort, the University of Oxford and Xi’an Jiaotong University have introduced an innovative machine-learning model that promises to revolutionize the field of simulating Phase-Change Materials (PCMs) in advanced memory technologies. This groundbreaking research, published in Nature Electronics, opens up new avenues for a deeper understanding of PCM-based devices, paving the way for enhanced performance and functionality.

Traditionally, the simulation of phase-change materials posed significant challenges due to the limitations of direct quantum-mechanical simulations, which could only handle relatively simple models with a limited number of atoms. However, this joint effort has yielded a machine learning model that can swiftly generate high-fidelity simulations, offering a comprehensive insight into the inner workings of PCM-based devices.

The heart of their innovation lies in a machine learning-based potential model, meticulously trained using quantum-mechanical data. This model boasts exceptional speed, enabling atomistic simulations of numerous heat cycles and intricate operations crucial for neuro-inspired computing, including cumulative SET and iterative RESET. Notably, this method provides a detailed description of technologically relevant processes within phase-change material memory devices, as exemplified by a model encompassing nearly half a million atoms in a device size of 40x20x20 nm³.

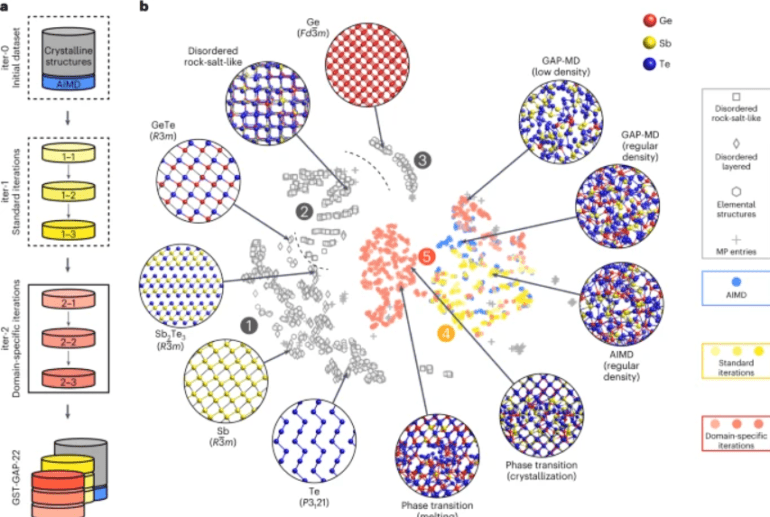

Through the application of machine learning-driven modeling, researchers have achieved fully atomistic simulations of phase shifts along the GST compositional line under real-world device geometries and conditions. This approach, employing interatomic potentials within the GAP framework and iteratively improving the resulting reference database, has unveiled the atomistic processes and mechanisms in PCMs at the ten-nanometer scale. The outcome is the ability to model a cross-point memory device with over 500,000 atoms, thanks to the model’s enhanced speed and precision.

To fuel their machine learning model, the research team curated a fresh dataset with labeled quantum mechanical data, enabling the precise modeling of atoms in PCMs across numerous heat cycles and simulated device operations. These promising results underscore the potential of employing ML for atomic-scale PCM-based device simulation, marking a significant milestone in the field.

The utilization of a machine learning (ML) model has led to a substantial enhancement in PCM GST simulation time and accuracy, facilitating atomistic simulations of memory devices with realistic shapes and programming conditions. Importantly, ML-driven simulations exhibit linear scalability with the size of the model system, making them adaptable to larger and more complex device geometries and extended timescales, leveraging the power of modern computing resources. This advancement is poised to unlock the ability to sample nucleation and observe atomic-scale grain boundary formation in large GST models under various conditions, including isothermal settings or temperature gradients, offering insights into nucleation barriers and critical nucleus sizes through ML-driven simulations combined with advanced sampling techniques.

Furthermore, the potential impact of interface effects on adjacent electrodes and dielectric layers in device engineering represents a fascinating avenue for future exploration. Enclosing PCM cells with aluminum oxide walls, for instance, has demonstrated a significant reduction in heat loss. However, finite element method simulations alone cannot explore the impact of these atomic-scale walls on thermal vibrations at the interface and PCM phase-transition capabilities. Atomistic ML models, equipped with extended reference databases, hold the promise of predicting minimal RESET energy, crystallization time for diverse device geometries, and microscopic failure mechanisms, thereby contributing to the optimization of architectural designs. In summary, the results presented here illuminate the tremendous potential of ML-driven simulations in shaping the future of PCM phases and PCM-based devices.

Conclusion:

This breakthrough in PCM simulations and memory device modeling has the potential to transform the market for advanced memory technologies. The ability to conduct atomistic simulations with unprecedented speed and accuracy opens up new possibilities for designing and optimizing PCM-based devices, ultimately leading to more efficient and advanced memory solutions. This development positions the University of Oxford and Xi’an Jiaotong University at the forefront of memory technology research, with potential applications spanning various industries.