TL;DR:

- BotBuilt utilizes robotics to lower costs and enhance efficiency in homebuilding.

- Rising median household incomes and dwindling home supply create a pressing need for innovation.

- The company’s focus is on automating the framing process, a key component in construction.

- Their flexible robotic systems offer a cost-effective and adaptable solution.

- BotBuilt empowers homebuilders by offering high-quality and affordable robotic labor.

- The company faces competition in the robotics homebuilding space but shows promising growth.

- BotBuilt secured $12.4 million in seed funding and plans to expand operations in 2024.

Main AI News:

Homes have become increasingly expensive and harder to attain, with the median household income for home buyers rising to $107,000 this year, up from $88,000 just last year, as reported by the National Association of Realtors. Simultaneously, the supply of homes for sale in the U.S. has reached an unprecedented low, showing no signs of recovery. While some may argue that rising prices and dwindling supply can drive a shift towards more sustainable housing options, startups like BotBuilt are making a compelling case for leveraging technology to reduce costs and mitigate the negative impacts of homebuilding.

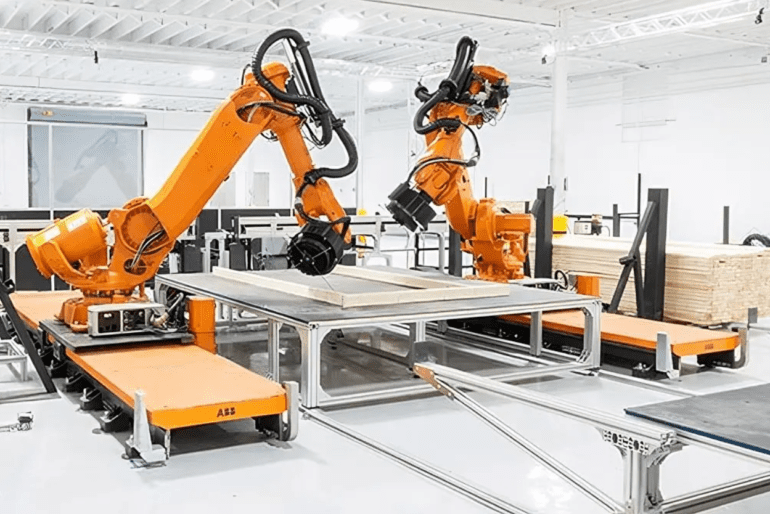

Founded in 2020 by Brent Wadas, Colin Devine, and robotics engineer Barrett Ames, BotBuilt has a bold mission: to create a robotic system capable of translating building plans into a series of precise machine commands. These commands are then executed by their innovative system, revolutionizing the homebuilding process.

The inspiration behind BotBuilt’s mission stems from personal experience, according to Barrett Ames. While a graduate student at Duke, Ames and his wife embarked on a home renovation project, recruiting friends and family to help. Through this endeavor, Ames gained valuable insights into the challenges and patterns of construction.

Ames notes, “The housing industry faces a significant shortage, and builders understand the urgency of addressing years of underbuilding. With increasing interest rates, many homeowners are reluctant to leave their current homes and associated rates, further intensifying the demand for new housing.”

BotBuilt’s system doesn’t start from scratch but focuses on a crucial aspect of homebuilding: framing construction. Their robotics efficiently assemble panels for walls, floor trusses, and roof trusses—the major framing components of homes. Impressively, their system offers flexibility, allowing for quick reprogramming to adapt to various frame designs, which sets them apart from previous attempts at automation in construction.

By automating the framing process, BotBuilt aims to significantly accelerate the pace of homebuilding while reducing costs. Typically, house framing costs range from $7 to $16 per square foot, including labor costs. Framing usually takes around a month, but factors like adverse weather and labor shortages can cause delays.

According to the National Association of Home Builders, over 55% of single-family homebuilders reported a shortage of skilled labor in 2021. BotBuilt steps in by providing services to homebuilders, operating robot-equipped factories that produce framing components, thus empowering builders to increase their volume and margins through high-quality and affordable robotic labor.

While BotBuilt faces competition in the robotics homebuilding sector from companies like Randek, Weinmann, House of Design, Diamond Age, and Mighty Homes, they are making steady progress. With nine homes already built and revenue at approximately $75,000, their growth trajectory is set to accelerate in 2024. Their plan includes shipping trusses built by their robotics while expanding general operations.

Ames is confident that their level of automation will enable them to achieve gross margins significantly higher than the industry standard of 30-40%. The company has already secured commitments from ten builders for over 2,000 homes and apartment units in their pipeline, with plans to build them as swiftly as possible.

To facilitate this expansion, BotBuilt has successfully raised $12.4 million in a seed funding round, with support from previous investors such as Ambassador Supply, Y Combinator, Owens Corning, and Shadow Ventures. This funding will be instrumental in growing their team from 13 to approximately 20 members, further propelling BotBuilt toward its mission of revolutionizing the homebuilding industry.

Conclusion:

BotBuilt’s innovative use of robotics in homebuilding addresses the challenges posed by rising costs and limited supply in the housing market. By automating the framing process, they offer a cost-effective and efficient solution for builders. While facing competition, their potential for higher margins and scalability positions them as a significant player in the evolving homebuilding industry.