TL;DR:

- A team of scientists has developed a novel 3D printing process for pills that can release pharmaceutical drugs at predetermined speeds.

- Geometrically shaped pills allow for precise control over drug dissolution in the body.

- The technique has significant potential in the pharmaceutical industry, offering personalized medicine and improved drug delivery.

- The research team utilized advanced computational methods and 3D printing technology to achieve their breakthrough.

- The inverse design strategy employed by the team is a first in the field, enabling the creation of pills with specific release profiles.

- The measured release curves of the printed pills closely matched the desired values, validating the accuracy of the technique.

- The market impact of this new pill production method is yet to be quantified, but the team has already patented their work.

Main AI News:

In a groundbreaking development, a team of brilliant scientists from the prestigious Max Planck Institute for Informatics in Saarbrücken, Germany, in collaboration with the esteemed University of California at Davis, has unveiled a cutting-edge process for 3D printing pills that can release pharmaceutical drugs at predetermined speeds. This innovative technique has the potential to revolutionize the pharmaceutical industry and pave the way for personalized medicine.

Led by the accomplished Dr. Vahid Babaei from the Max Planck Institute and the distinguished Prof. Julian Panetta of UC Davis, the research team showcased their remarkable achievement in a recently published research paper. They demonstrated how pills could be 3D printed with specific shapes to regulate the speed at which they dissolve within the human body. This breakthrough approach harnesses the ease of control offered by geometric shapes, presenting a superior alternative to conventional drug-delivery methods like intravenous infusion.

Controlling drug levels in patients is of paramount importance in healthcare, and this ground-shaking method promises to meet that need with precision. It has immense potential within the pharmaceutical industry and could herald a new era of point-of-care, personalized medicine. Furthermore, the applications extend beyond pharmaceutics, as this novel technology can also be employed in the production of catalytic bodies and coarse granular fertilizers.

Dr. Babaei, the visionary Research Group Leader of the Artificial Intelligence-Aided Design and Manufacturing Group at Max Planck Institute for Informatics, expressed his confidence in the transformative power of 3D printing. He remarked, “I am convinced that point of care, personalized medicine is around the corner, and 3D printing will play a major role.”

The research team employed a multifaceted approach, combining advanced computational methods, mathematical modeling, and state-of-the-art 3D printing technology based on Fused Deposition Modeling (FDM). By conducting simulations using topology optimization, they developed intricate designs that were subsequently inverted to find specific shapes with desired dissolution properties. Practical experiments were then conducted to validate these predictions. This innovative inverse design strategy, pioneered by the research team, is a remarkable first in the field.

To realize their groundbreaking experiments, the researchers utilized a Prusa i3 MK3s FDM 3D printer equipped with a 0.2 mm Kaika nozzle from Tecdia Co. AquaSys 120 from Infinite Materials Solutions, a water-soluble filament commonly used for support structures, was employed in the printing process. Once the desired components were printed, they were immersed in distilled water, and a sophisticated camera system was employed to measure the dissolution speed of the pieces. This image-based system proved to be significantly faster and simpler than traditional methods, which often require expensive and specialized equipment.

The measured release curves of the printed pills were found to be remarkably close to the desired values, confirming the accuracy of the inverse design strategy. This breakthrough validates the notion that specific shapes can be leveraged to determine precise release rates for pharmaceutical drugs, opening up a world of possibilities for targeted and controlled drug delivery.

While the total addressable market for this groundbreaking pill production method has not yet been quantified, the research team has already taken steps to protect their innovative work by obtaining patents. Dr. Babaei emphasized the team’s commitment to translating their research into practical applications, exemplified by the launch of their spin-off project for the laser industry, aptly named Oraclase.

Leveraging the power of 3D printing in the pharmaceutical field is not entirely new. In 2016, Aprecia Pharmaceuticals made headlines when they obtained approval from the U.S. Food and Drug Administration for their Spritam medication, marking the first 3D-printed pharmaceutical to successfully complete the rigorous FDA process. Spritam, designed to treat various seizures, is 3D printed as an instantly dissoluble tablet, making it more accessible to patients who struggle with swallowing traditional pills.

While Aprecia’s offering bears some similarities to this new shape-oriented process, Dr. Babaei points out a fundamental distinction. He explains, “To my understanding, Spritam has a single dissolution mode – a fast, immediate one. In our case, we let the user practically draw any release profile (fast or otherwise) and then compute the shape accordingly.” This unparalleled flexibility sets the groundbreaking technique developed by the Max Planck Institute and UC Davis apart from existing methods.

Another noteworthy advancement in the realm of pharmaceutical 3D printing occurred in 2020 when a research team from Greece and Italy harnessed semi-solid extrusion 3D printing to modify tablets, enabling customizable and patient-specific drug release rates. Rather than 3D printing the entire pills, the scientists used 3D printing technology to partially coat the tablets with glycerides, enabling precise regulation of the release of Active Pharmaceutical Ingredients (APIs) within the tablets. This achievement facilitated personalized drug release rates tailored to the unique needs of each patient.

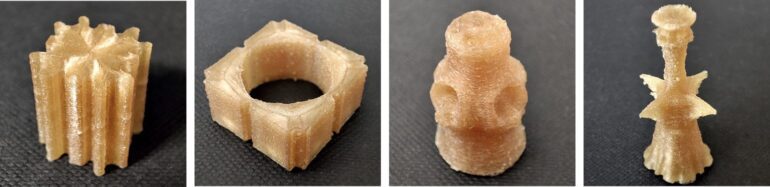

A 3D printed pill. Photo via Max Planck Institute for Informatics.

Conclusion:

The development of 3D printing pills with controlled drug release represents a significant advancement in the pharmaceutical industry. This groundbreaking technique offers the potential for personalized medicine and improved drug delivery, addressing the critical need for precise control over drug levels in patients. The ability to shape pills to determine specific release rates opens up new possibilities for targeted and controlled drug delivery. While the market impact is still to be determined, the patented technology sets the stage for transformative changes in pharmaceutical manufacturing and patient care.