TL;DR:

- German startup Micropsi Industries has introduced MIRAI, an AI-powered control system that enables robots to handle variations in shape, position, color, and lighting conditions in their workspaces.

- MIRAI simplifies robot programming and allows them to learn tasks through observation, eliminating the need for extensive programming knowledge.

- The system comprises a MIRAI controller, a six-axis robot, a force-torque sensor, an end effector, a camera, and a ring-light.

- Micropsi Industries collaborates with DEPRAG to provide a robotic screwdriving system that compensates for variations in part position and manufacturing tolerances.

- Siemens Energy utilizes Micropsi’s technology to automate the refurbishment of gas turbine vanes, improving efficiency and precision.

- Auto parts supplier ZF implements Micropsi’s system for machine tending, overcoming challenges such as unpredictable ring positions and variations in crate shape and lighting conditions.

Main AI News:

The integration of artificial intelligence (AI) into manufacturing processes continues to revolutionize the industry, enhancing automated inspection, optimizing product designs, and leveraging extensive process data analysis to prevent defects. Now, AI is empowering robots to perform tasks with greater precision and adaptability.

German startup Micropsi Industries GmbH has introduced MIRAI, a groundbreaking control system that enables robots to handle variations in shape, position, color, and lighting conditions within their workspaces. By harnessing the power of AI, MIRAI generates real-time robot movements and can automatically respond to changes in the target object’s motion. The system excels at controlling the initial and final centimeters of the robot’s path, eliminating the need for rigid fixturing of parts.

Moreover, MIRAI simplifies the programming process for robots. Equipped with MIRAI, robots can learn tasks through observation, making them highly trainable and adaptable for various process steps. The beauty of this system lies in its accessibility, as no prior knowledge of programming or AI is required.

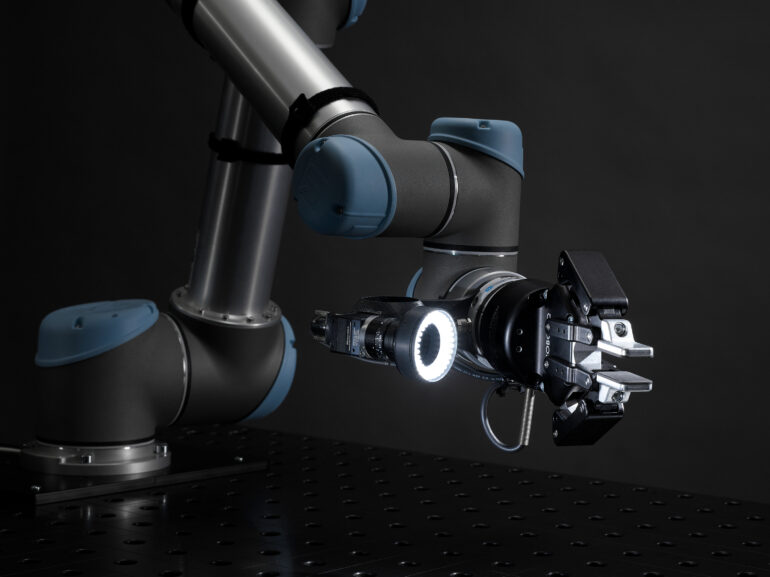

The MIRAI system comprises a MIRAI controller, a six-axis robot (supplied by FANUC or Universal Robots), a force-torque sensor, an end effector, a camera (supplied by Micropsi Industries), and a ring-light. This comprehensive setup augments the robot’s native controller, enabling it to perceive and interact effectively with its work environment. Powered by AI, MIRAI-enabled robots observe human actions and replicate them, capturing these observations through a camera affixed to the robot’s wrist or positioned near the workspace. These recordings are then transformed into a vision-based, real-time control schema that governs the robot’s actions.

In an exciting collaboration, Micropsi Industries and fastening specialist DEPRAG have developed a robotic screwdriving system capable of compensating for variations in part position, fastening angle, and manufacturing tolerances. Screwdriving with a six-axis robot is notoriously challenging without precise guidance. By combining their expertise, the two companies offer customers a robust and profitable automation solution, simplifying access to automation and streamlining operations.

The DEPRAG-Micropsi system also enables robots to install screws in assemblies as they pass along a conveyor, expanding the scope of its applications. With its versatility, the system can be deployed across diverse industries, including appliances, electronics, automotive parts, and agricultural machinery.

One remarkable application of Micropsi’s technology lies in the refurbishment of gas turbine vanes by Siemens Energy. After four years of operation, these vanes require reshaping and resurfacing. Notably, these vanes contain numerous tiny holes, approximately 2 millimeters in width, which were used for air cooling during their previous usage. The challenge during refurbishment lies in filling each hole with solder paste using a thin needle.

Addressing these challenges head-on, the MIRAI control system guides a six-axis robot through the solder paste dispensing process. The AI-powered robot compensates for variations in hole position, vane shape, and overall vane condition. Seamlessly navigating from one hole to another, the MIRAI system efficiently inserts the needle into each hole while the robot’s native controller takes care of the soldering paste dispensing and other aspects of the task. Siemens engineers successfully trained the MIRAI-powered robot in just a few days, highlighting the system’s user-friendly nature.

Meanwhile, ZF, an esteemed auto parts supplier based in Friedrichshafen, Germany, sought to automate machine tending at a high-volume milling station dedicated to gear manufacturing. The task at hand involved picking metal rings from a crate and placing them onto a conveyor, forming the raw material for subsequent manufacturing steps. However, this process presented multiple challenges for automation:

- The positions of the rings within the crate were unpredictable due to shifts during transportation.

- The crate’s position varied by 20 to 30 millimeters in all directions upon delivery.

- The crate’s shape exhibited deviations, with sides sometimes being pressed inward by 20 to 30 millimeters.

- Direct sunlight exposure affected approximately one-third of the rings, despite protective measures.

- Bubble foil inside the crate covered parts of the rings.

- The appearance of the rings varied due to factors such as oil and rust, posing challenges for the vision system.

Addressing these complexities, Micropsi developed an advanced system that outperforms conventional approaches in terms of speed and reliability. The comprehensive setup includes a MIRAI kit with the control box and camera, a Universal Robots UR10e cobot, an OnRobot force-torque sensor, and a Schunk gripper.

Upon arrival, the metal rings within the crate are organized in layered beds, tightly packed on their flat sides. Leveraging its native controller, the UR robot is programmed to maneuver above individual rings within the crate. Once the robot is positioned above a ring, the MIRAI system takes control, guiding the robot to the nearest ring and aligning the gripper accordingly. Subsequently, the robot’s native system resumes control, picking up the ring, placing it on the conveyor, and ensuring a seamless transition in the manufacturing process. Remarkably, the training process for the cobot to execute its designated tasks merely took four days.

To optimize the vision system’s perspective, Micropsi designed three gripper jaw extensions, enabling the system to view the parts from a perpendicular angle. By attaching 3D-printed plastic fingers with grooves to the end of these extensions, a stronger grip on the rings is ensured, even when their surfaces are challenging to handle due to various factors such as oil and rust.

Conclusion:

The integration of AI into robotic assembly systems, as demonstrated by Micropsi Industries’ MIRAI, is revolutionizing the manufacturing market. By enabling robots to handle variations, learn through observation, and simplify programming, AI empowers manufacturers to achieve greater flexibility, efficiency, and accuracy in their production processes. Collaborations with companies like DEPRAG and Siemens Energy further expand the applications of AI in areas such as screwdriving and refurbishment. This advancement in robotic assembly systems signifies a transformative shift in the market, paving the way for increased automation and productivity in various industries. Businesses that embrace these innovations can gain a competitive edge by optimizing their manufacturing operations and streamlining access to automation solutions.