- AI algorithm enhances 3D printing efficiency for complex structures.

- A study from WSU shows potential in artificial organs, flexible electronics, and wearable biosensors.

- The algorithm iteratively improves designs, optimizing printing settings for better outcomes.

- The process allows for faster, cost-effective production of lifelike organ models.

- A method is generalizable and applicable to various industries beyond biomedical devices.

Main AI News:

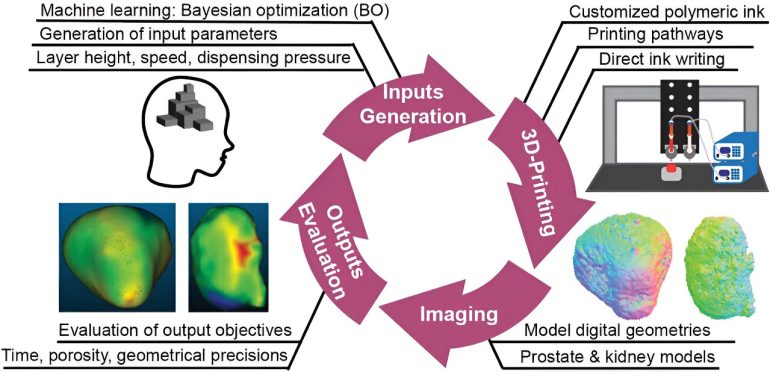

An advanced AI algorithm transforms 3D printing by enabling more efficient manufacturing of intricate structures. Highlighted in a study from Washington State University, published in Advanced Materials Technologies, this innovation streamlines the production of complex designs for applications ranging from artificial organs to flexible electronics and wearable biosensors. Through extensive training, the algorithm was able to iteratively improve and produce the most refined versions of kidney and prostate organ models, resulting in 60 progressively enhanced iterations.

The growing adoption of 3D printing has allowed industrial engineers to quickly convert digital designs into a wide array of products, including wearable technology, batteries, and aerospace components. However, fine-tuning the printing process—selecting materials, configuring the printer, and adjusting dispensing pressure—remains a complex and resource-intensive task, given the myriad of potential settings that must be considered.

In advancing lifelike 3D-printed models of human organs, the WSU research team aimed to replicate the mechanical and physical properties of real organs, including detailed structures like veins and arteries. These models are essential for surgical training and implant evaluation.

To optimize the 3D printing process, the research team employed Bayesian Optimization, an AI technique, to identify the best printing settings. The algorithm was trained to optimize three key objectives: the model’s geometric precision, weight (or porosity), and printing time. Porosity is particularly crucial for surgical practice, as it directly influences the mechanical properties of the model.

The successful balance of these objectives led to the production of high-quality printed objects, regardless of the material or shape used. The project also benefited from its interdisciplinary approach, combining expertise from different fields to achieve well-rounded results. Initially, the AI was trained to print a prostate model for surgical rehearsal, and with minor adjustments, it was later adapted to produce a kidney model.

This method has the potential to extend beyond biomedical devices, offering solutions for other complex manufacturing challenges in various fields.

Conclusion:

Integrating AI into 3D printing marks a significant advancement in the manufacturing sector. By optimizing the complex and resource-intensive process of 3D printing, this technology enables faster and more efficient production of intricate designs. For the market, this development means reduced costs and shorter production cycles for high-quality, customized products. Industries such as healthcare, electronics, and aerospace benefit immensely, as they can rapidly produce sophisticated components and devices with greater precision and reliability. This innovation will likely drive further adoption of 3D printing across various sectors, fostering a new era of customization and efficiency in manufacturing.