TL;DR:

- Michigan-based company RoboTire introduces a robotic solution for tire-changing.

- The robot can change a set of four wheels in 23 minutes, twice as fast as a human under normal conditions.

- It utilizes two six-axis arms, powered by AI and equipped with cameras to scan and identify wheel details.

- The arms unbolt the lug nuts, remove the wheel, and replace it with a new one or a fresh tire.

- Human supervision is currently required, but the system relays important data to a tire-changing machine.

- The robot learns and adapts to different wheel sizes and bolt patterns, improving its performance over time.

- Advantages include reduced physical strain on mechanics and increased productivity.

- The goal is to develop a fully-autonomous solution in the future.

- Creamery Tire in Pennsylvania has experienced benefits, optimizing labor and productivity.

- Most operators are expected to see payback within a year due to increased productivity and reduced labor costs.

Main AI News:

In a world where technology is reshaping industries at an unprecedented pace, it seems that even the realm of tire-changing is not immune to the robotic revolution. The emergence of Michigan-based company RoboTire brings forth an innovative solution that is set to transform the way we handle this essential automotive task. With efficiency at its core, this cutting-edge robotic system is making waves in the industry.

With a remarkable feat, the RoboTire robot can change a complete set of four wheels in a mere 23 minutes. While this may seem relatively longer when compared to the lightning-fast pit stops seen in Formula 1 races, it is a significant improvement over the time taken by a human technician. Under normal operating conditions, the robot’s speed is twice that of a human, making it a game-changer in the field of tire-changing technology.

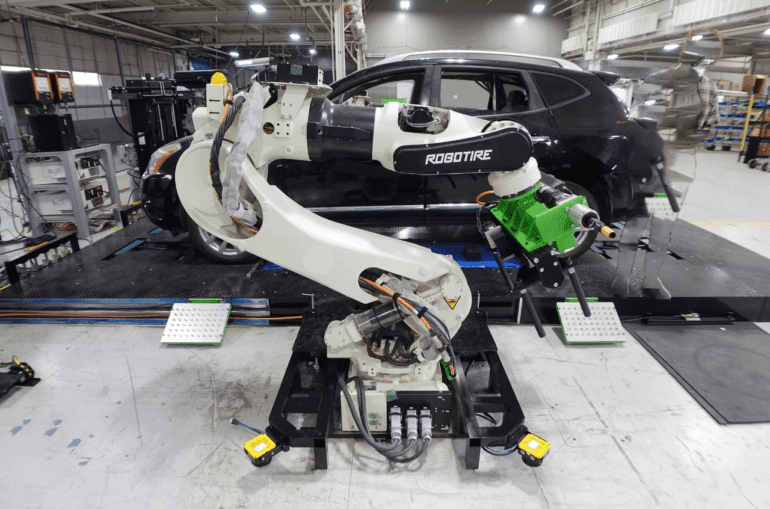

At the heart of the RoboTire system are two six-axis arms, each dedicated to one side of a car. These arms, akin to the ones used by automakers on assembly lines, possess remarkable strength and dexterity. Powered by artificial intelligence (AI), the robot employs cameras to meticulously scan the car’s wheels, accurately noting their positions and bolt patterns. Leveraging this data, the arm’s in-built torque wrench then proceeds to expertly unbolt each lug nut individually. The arm deftly removes the wheel, swiftly replacing it with a new one or a freshly changed tire.

While human supervision is currently necessary throughout the process, and a technician is still required to transport the dismounted wheel to a tire-changing machine, the RoboTire’s cameras capture crucial information about the wheel size and tire type. This data is seamlessly relayed to the tire-changing machine, streamlining the entire operation and saving valuable time.

Thanks to its AI capabilities, the RoboTire system is constantly learning. Regardless of the wheel size or bolt pattern, the machine adapts effortlessly to any challenge it encounters. It can even handle wheels caked in mud or snow, as long as the lug nuts’ edges remain visible. The network of four stores equipped with RoboTire machines ensures that the robots continuously improve their performance. As they “train” on a diverse range of wheels and sizes, their collective knowledge evolves, enabling them to become faster and more efficient over time.

The advantages of this technological marvel are evident, particularly when it comes to the labor-intensive aspects of tire changing. Mechanics no longer need to grapple with the physical strain of lifting heavy wheels on and off cars. This innovation frees them to focus on other crucial aspects of their work. While concerns about job security may arise, RoboTire’s website dismisses such worries, emphasizing that the system aims to enhance technician safety. Nevertheless, the question lingers: what lies ahead for the future of tire-changing as this autonomous solution continues to advance?

Rich Shainline, the owner of Creamery Tire in Pennsylvania, shared his positive experience with the RoboTire robot. He highlighted how this technological marvel has helped his company tackle the ongoing labor shortage. By leveraging the robot’s capabilities, Shainline has been able to optimize productivity, as one technician can handle the task that previously required two. The impact on efficiency and the potential reduction in labor costs make the RoboTire system an enticing prospect for many operators.

While specific pricing details have yet to be disclosed to the public, RoboTire expects that most operators will experience a significant return on investment within a year. This calculation takes into account the increased productivity achieved through the robot’s tire-changing efficiency, as well as the potential reduction in labor costs. With such promising prospects, the RoboTire system is poised to reshape the tire-changing landscape and revolutionize the industry as a whole.

Source: Carscoops

Conlcusion:

The introduction of RoboTire’s innovative tire-changing technology signifies a significant development in the market. The system’s ability to change a set of four wheels in a fraction of the time taken by human technicians provides a competitive edge for operators in the tire-changing industry. The automation and AI-driven capabilities of RoboTire enhance efficiency, reduce labor costs, and optimize productivity.

Moreover, the potential for a fully-autonomous solution in the future indicates a transformative shift in the market landscape. As operators witness the positive impact on their operations, we can anticipate increased adoption of similar automated systems, leading to a more streamlined and technologically advanced market for tire-changing services.