TL;DR:

- Buchwald-Hartwig reaction, a crucial tool in organic synthesis, finds widespread use in pharmaceutical industry.

- Illinois researchers collaborate with Hoffman La-Roche to develop machine learning tool.

- Tool predicts optimal conditions for high-yielding reactions in minutes, eliminating the need for lengthy experimentation.

- Machine learning model trained to accelerate identification of substrate-adaptive conditions for carbon-nitrogen bond formation.

- Tool’s predictions were experimentally validated, showcasing impressive performance in diverse couplings.

- Tool emulates chemical intuition, enhancing prediction capabilities over time.

- Cloud-based version to be launched, promoting global accessibility and data-driven refinement.

- Open-source code empowers wide adoption.

- Interface aims to provide user-friendly experience, expediting research processes.

Main AI News:

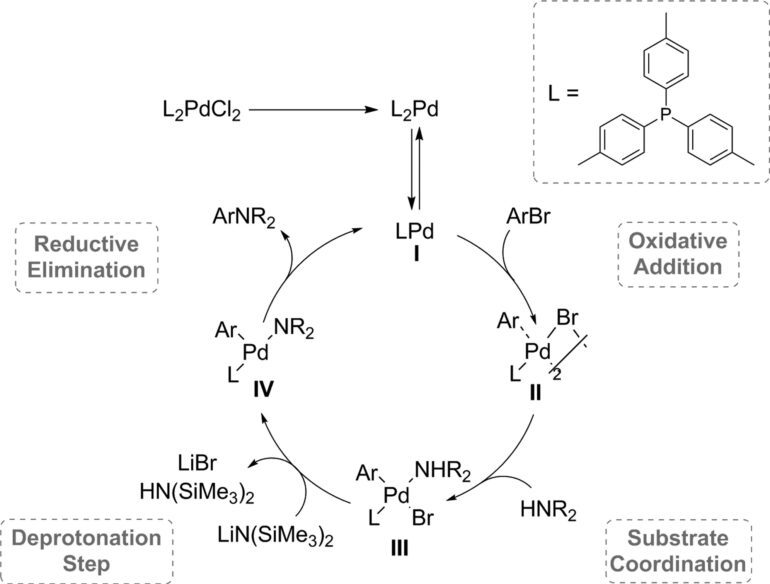

In the ever-evolving landscape of organic synthesis, the Buchwald-Hartwig reaction has emerged as a pivotal technique over the past two decades. This carbon-nitrogen bond forming reaction, hailed for its significance in the pharmaceutical sector, has enabled the efficient creation of nitrogen-containing compounds found abundantly in natural products and pharmaceuticals. Despite its transformative potential, the road to optimizing this reaction’s efficacy has been paved with arduous and time-intensive experimentation.

A paradigm shift is on the horizon, driven by the collaboration between Illinois researchers and chemists at Hoffman La-Roche, a pharmaceutical powerhouse based in Switzerland. Their ingenuity has birthed a remarkable machine learning tool that promises to unravel the complexities of the Buchwald-Hartwig reaction swiftly and effectively. What once demanded prolonged trial-and-error endeavors can now be discerned within minutes, thanks to this groundbreaking advancement.

Detailed in a recent article published in Science (DOI: 10.1126/science.adg2114), the brainchild of Illinois chemistry professor Scott Denmark and Ian Rinehart, a recent PhD graduate from Denmark’s lab, outlines the development, training, and validation of their machine learning model. This innovation holds the potential to expedite the identification of optimal substrate-adaptive conditions for the palladium-catalyzed carbon-nitrogen bond forming reaction.

This transformative reaction boasts broad applicability, catering to a diverse array of reactant pairings with numerous variables to manipulate. As Denmark aptly stated, “And that’s what we have figured out.” Rinehart further elucidates that while user guides and cheat sheets have evolved over three decades, the reliance on experimentation remains, often resembling a laborious trial-and-error process within the laboratory.

The void for an intervention by informatics methods within the pharmaceutical industry has not gone unnoticed. As Denmark remarks, previous attempts to harness extensive databases for predictive tools have fallen short due to the unreliability of information within the literature. The marriage of data science and chemistry has beckoned, and this collaboration emerges as a beacon of promise, equipped with a machine learning tool designed to reshape the landscape.

The construction of this machine learning tool hinged upon the creation of an experimental dataset that traverses a labyrinth of reactant pairings across diverse reaction conditions. Neural network models embarked on the task of assimilating a wide scope of C-N couplings, facilitated by a systematic experiment design process. The crux of this endeavor lay in collecting a vast pool of potential data points and conducting thousands of experiments to construct a robust information repository for modeling.

Ian’s pioneering contribution resonates in his adeptness at formulating a workflow that distills pertinent experiments, resulting in a predictive model sustained by around 3,500 experiments, obviating the need for an unwieldy database. Experimental validation further fortified their machine learning tool’s credibility. As Denmark articulates, the tests yielded favorable results, aligning with anticipated outcomes.

The ultimate litmus test lay in the rigorous experimental validation, wherein their models exhibited remarkable performance. A staggering ten products were isolated, with an impressive yield exceeding 85 percent. These outcomes were derived from an assorted range of couplings that deliberately challenged the models, signifying their robustness.

What truly sets this machine learning tool apart is its ability to emulate chemical intuition, akin to a seasoned expert. Rinehart draws a parallel between the models’ intuition and that of experienced chemists, elucidating that the model’s prowess is akin to a finely honed instinct. This intuition is poised to refine over time as the user base grows, continually enhancing the prediction capabilities of the tool.

Data science’s convergence with chemistry is an exhilarating frontier, and Denmark underscores the symbiotic relationship within this amalgamation. The imminent launch of a cloud-based version of the workflow promises accessibility to scientists worldwide, fostering a collaborative environment that contributes to refining the model. Furthermore, the democratization of knowledge is upheld through the open-source nature of the code, enabling widespread adoption and application.

Rinehart’s aspirations extend to a more user-friendly interface, one that empowers users to effortlessly sketch two molecules, input them into the program, and receive predictions within minutes. This streamlined process holds immense promise, empowering researchers in academic realms to expedite their pursuits and unravel solutions swiftly.

Conclusion:

This innovative machine learning tool has the potential to reshape the pharmaceutical synthesis landscape. By swiftly predicting optimal conditions for carbon-nitrogen bond formation, it accelerates research, streamlines experimentation, and democratizes access to cutting-edge insights. This convergence of chemistry and data science holds promise for enhanced efficiency and innovation within the market, offering researchers a powerful tool for faster, more informed decision-making.