TL;DR:

- Talim code, an ancient symbolic system, has long been used in Kashmir’s carpet weaving.

- The traditional process involved manual encoding, leading to time-consuming errors.

- Computer software now streamlines the design and creation of the talim code.

- AI is being trained to understand and assist with the talim code.

- This innovation aims to accelerate carpet production and meet evolving consumer demands.

- The Indian carpet industry faces competition from Turkey and China.

- Innovation integrates technology into various aspects of carpet production.

- An official tagging system ensures the authenticity of hand-knotted Kashmiri carpets.

- The industry employs around 50,000 workers in Jammu and Kashmir, contributing £36 million ($28 million) annually.

- These advancements offer hope for the industry’s future and economic growth in the region.

Main AI News:

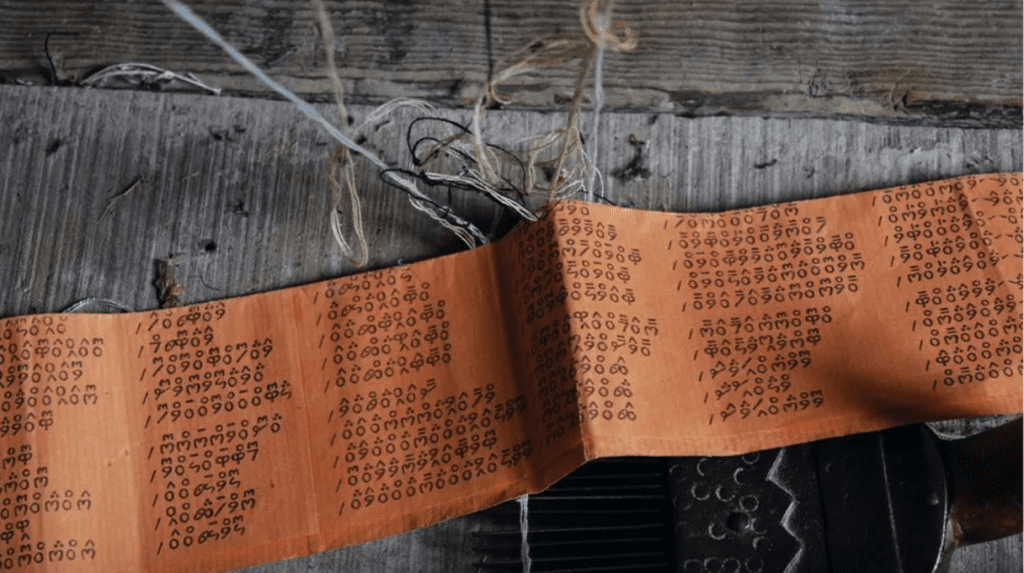

In the heart of Kashmir’s rich tradition of handwoven carpets and rugs lies a centuries-old symbolic code known as “talim.” This intricate code has served as the backbone of carpet design and a means of communication for generations of weavers. Mohammad Rafiq Sofi, who embarked on his carpet-weaving journey at the tender age of eight, has spent nearly five decades honing his craft using talim designs.

During his long tenure in the industry, Mr. Sofi witnessed significant transformations. In the early days, it could take more than half a year to complete a single carpet. The process entailed a designer creating a carpet design, which a talim expert would then encode. These coded instructions were sent to weavers in small sections, guiding them on thread knots and color choices. With each section representing only a fraction of the carpet, constant communication between designers and weavers was necessary.

This intricate process made detecting errors cumbersome and time-consuming. However, contemporary computer software has streamlined this age-old practice, enabling Mr. Sofi to complete a carpet in just six weeks. While the weaving and knotting remain manual tasks, computer software now handles the design and creation of the talim code. This advancement provides Mr. Sofi with the advantage of seeing the entire design at once, eliminating the need to work with small sections and allowing for early error detection.

Mehmood Shah, the director of Handloom & Handicrafts for the government of Jammu and Kashmir, emphasizes that this innovation aims not to disrupt the artistic essence of carpets but rather to accelerate design availability. As technology firms explore artificial intelligence (AI) applications, the process is poised to take another leap forward.

One such firm is International Virtual Assistance, where Aby Mathew serves as the Chief Operating Officer. The company specializes in data analysis and is training an AI system to comprehend the talim code by presenting it with images of carpets and corresponding talim instructions. While a human is still required to write the code, Mr. Mathew anticipates that this AI assistance will expedite manufacturing by decoding talim instructions for weavers.

“Weavers will be able to try out new patterns, update classic themes to suit contemporary tastes, and produce one-of-a-kind, custom carpets,” says Mr. Mathew.

As India’s affluence grows, there is an escalating demand for carpets that the traditional industry may struggle to meet. Mr. Mathew explains, “The tastes of customers are evolving, with a growing desire for carpets that are fashionable, long-lasting, and low maintenance. Conventional carpet-making techniques are frequently labor-intensive and sluggish – they might not be able to satisfy these needs.”

Aditya Gupta, the founder of Rug Republic, established the company 32 years ago, employing approximately 5,000 individuals and producing up to 15,000 rugs each month. He underscores the importance of innovation in the industry’s survival, especially in the face of stiff competition from rivals in Turkey and China.

“The Indian carpet industry is an interesting case, where it is not only about moving forward with new tech, but rather moving the old and the new hand in hand. The innovation now is oriented towards creating designs that cannot be copied by machines while still using traditional techniques,” Mr. Gupta asserts.

At Rug Republic, technology has been integrated into various aspects of carpet production, including design, washing, drying, and moisture level monitoring. In addition to traditional wool, the company has experimented with materials like recycled denim, cotton, and leather.

Despite these innovations, Mr. Gupta remains a staunch advocate for preserving traditional, handmade methods. “The manufacturing side of things still needs to be traditional and handmade as that is the main charm the consumers seek.”

The industry has also benefited from an official tagging system that identifies genuine hand-knotted Kashmiri carpets. Buyers can scan a QR code to verify the carpet’s designer and production details, ensuring authenticity and quality.

“If the [Handicrafts] department hadn’t taken this step, maybe this trade in handwoven carpets would have died in a few years,” remarks carpet designer Shahnawaz Ahmad.

This thriving industry plays a vital role in the local economy, employing approximately 50,000 workers in Jammu and Kashmir and contributing to an annual production value of around £36 million ($28 million). The recent advancements in carpet making offer renewed hope to veterans like Feroz Ahmad Bhat, who have been weaving carpets for decades. Mr. Bhat reflects on the transformation: “In my early days, our earnings were good and a lot of people were involved with this work. Then a time came when wages were very low. But now new designs have been introduced, and this work has picked up pace again. Now it’s flourishing again.“

Talim code shows where to knot the carpet threads and what colour to use. Source: BBC

Conclusion:

The fusion of tradition and technology in India’s carpet weaving industry, with AI-driven enhancements and streamlined processes, promises to meet the evolving demands of consumers. As the market shifts toward fashionable, durable, and low-maintenance carpets, this innovation positions the industry to stay competitive amid global challenges, ensuring continued growth and economic benefits for the region.