- BMW’s Munich plant will produce electric vehicles exclusively by 2027.

- A €650 million investment initiates construction of new assembly lines and a body shop.

- Neue Klasse sedan marks the beginning of BMW’s electric vehicle lineup.

- Production diversification includes facilities in Hungary, China, and Mexico.

- Focus on alternative technologies like hydrogen remains crucial.

- Digitalization and AI enhance workforce training and process optimization.

Main AI News:

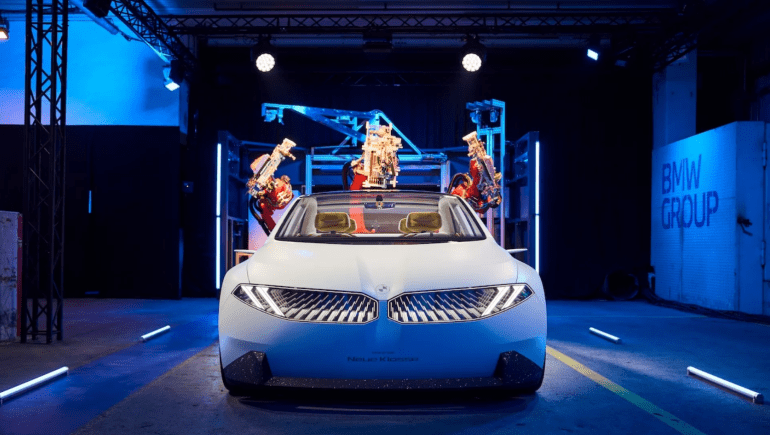

In a bold move towards sustainable mobility, BMW announces its Munich factory’s transformation to exclusively produce electric vehicles by 2027. This strategic shift aligns with the company’s commitment to e-mobility and is facilitated by a substantial €650 million investment. The investment kickstarted the construction of new assembly lines and a body shop, utilizing space vacated after halting internal combustion engine production in 2023.

Plant Munich Director, Peter Weber, expresses excitement about guiding the facility towards this electric future, emphasizing Munich’s significance as BMW’s core. The transition commences with the production of the Neue Klasse sedan, symbolizing BMW’s legacy and innovation. The Neue Klasse, originally introduced in the 1960s, now undergoes a revival tailored for the electric era, with plans for six new models within two years.

While the Munich plant remains the cornerstone for traditional BMW models, production diversification is evident. The introduction of the first Neue Klasse sedan in Munich underscores the plant’s prestigious status. However, production will extend to other locations like China and Mexico, with Hungary designated for manufacturing high-voltage batteries for an innovative 800v architecture, emphasizing BMW’s global strategy.

Despite the electric focus, BMW acknowledges the importance of alternative technologies, notably hydrogen. Board member Milan Nedeljković emphasizes the company’s commitment to flexibility, ensuring the Munich assembly line can adapt to future energy solutions. While internal combustion technology investment ceases, BMW remains agile, prepared for emerging technologies.

Driving this transformation is BMW’s embrace of digitalization and artificial intelligence (AI) through its ‘iFactory’ concept. Plant Director Weber underscores AI’s role in supporting rather than replacing the plant’s workforce. Digitalization enhances training methods, ensuring employees master tasks with precision. Augmented reality facilitates apprentices’ learning, optimizing processes and quality assurance.

Employees welcome these advancements, recognizing their contribution to efficient production. Integrating AI enhances safety, with transport robots operating more effectively. BMW emphasizes digitalization’s role in empowering its workforce and optimizing processes, ensuring a seamless transition towards an electric future.

Conclusion:

BMW’s decision to transform its Munich plant into an electric-only facility integrated with AI signifies a strategic move towards sustainability and innovation in the automotive market. This transition underscores BMW’s commitment to embracing alternative energy solutions and leveraging digitalization to optimize production processes, ensuring its competitiveness in a rapidly evolving industry landscape.