TL;DR:

- AI and machine learning are revolutionizing supply chains, leading to reduced inventory and improved service levels.

- Industry 4.0 technologies enable accurate demand forecasting, efficient inventory management, and better collaboration with suppliers.

- Automation through machine learning is transforming back-office tasks, logistics, warehouse management, quality control, and inventory management.

- Predictive analytics, autonomous vehicles, robotics, blockchain, IoT, and digital twins are key trends to watch out for.

- ML-powered supply chains pave the way for agility, data-driven decision-making, and effective disruption management.

Main AI News:

In today’s rapidly evolving business landscape, Industry 4.0 is ushering in a new era of innovation and efficiency. At the forefront of this transformation are cutting-edge technologies such as artificial intelligence (AI) and machine learning (ML). These powerful tools have the potential to revolutionize global supply chains, enabling businesses to streamline operations and maximize productivity. According to recent research, companies embracing AI have witnessed a remarkable 35% reduction in inventory and a staggering 65% increase in service levels. Meanwhile, ML empowers organizations to automate complex and repetitive tasks, leading to significant time savings and a substantial reduction in human errors.

Harnessing the true potential of data is a critical challenge in optimizing supply chain efficiency. However, with the advent of Industry 4.0 technologies, businesses can leverage data-driven insights to achieve accurate demand forecasting, enhance inventory management, and foster better collaboration with suppliers. Traditional supply chains and legacy systems, exposed by the COVID-19 pandemic and its associated disruptions, have prompted industry leaders to explore innovative solutions beyond the conventional. Consequently, the widespread adoption of AI, ML, and the Internet of Things (IoT) has become the cornerstone of building intelligent supply chains.

Today, supply chain leaders are embracing a wide array of applications powered by these transformative technologies. By 2025, it is projected that 38% of businesses will integrate AI and ML into their supply chain and manufacturing processes. Let us explore some key areas where ML can have a profound impact on supply chain management through automation.

Back-office automation: In this domain, intelligent automation blends conversational AI with robotic process automation to streamline tasks like document processing. ML programs effectively handle repetitive assignments, thereby limiting human involvement to monitoring or supervision.

Logistics automation: E-commerce giants like Amazon.com, along with pioneering companies like Tusimple and Nuro, are making substantial investments in transport automation technologies, including self-driving trucks, IoT, and blockchain. These innovations optimize delivery routes, enhance safety, and provide real-time shipment tracking and monitoring.

Warehouse automation: Major players like Ocado are revolutionizing the market with automated warehouse management systems driven by ML. This integration significantly boosts productivity, efficiency, and safety, setting new benchmarks for the industry.

Automated quality management: Computer vision systems empowered by ML enhance accuracy and productivity on production lines, ensuring high-quality finished products that meet rigorous standards.

Automated inventory management: Bots equipped with computer vision, AI, and ML is capable of automating repetitive tasks such as real-time scanning. While inventory-scanning bots can be employed in retail stores, it is crucial to carefully assess the feasibility and long-term benefits to mitigate the risk of failure.

The utility of ML in supply chain management extends far beyond the warehouse walls. From accurate demand forecasting to the instant resolution of customer queries, ML plays a pivotal role in optimizing every aspect of supply chain operations.

Now, let’s explore the top trends in AI and ML that supply chain managers need to watch out for:

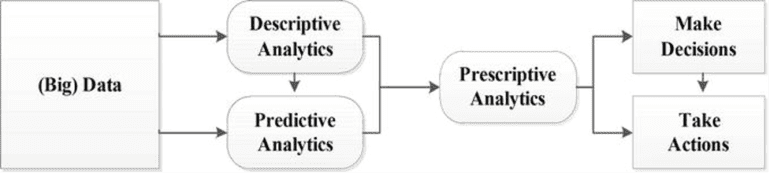

Predictive analytics: By harnessing the power of AI, supply chain managers can leverage predictive analytics to forecast demand, optimize inventory levels, and reduce costs. Sophisticated tools can analyze vast amounts of data, including historical sales, weather patterns, and social media trends, to generate precise demand forecasts and supply chain recommendations.

Autonomous vehicles: Drones and self-driving trucks hold the promise of revolutionizing the supply chain industry by driving efficiency and cost reduction. These vehicles optimize delivery routes, improve safety, and provide real-time shipment tracking and monitoring.

Robotics: In supply chain processes such as picking, packing, and sorting, robots equipped with ML can learn from human operators and optimize their movements to increase efficiency while minimizing errors. They can perform tasks autonomously, requiring minimal human intervention.

Blockchain technology: The integration of blockchain in supply chains improves transparency, traceability, and security. Data stored on a blockchain enables users to detect and prevent fraud, track products, and ensure compliance with regulations.

Internet of Things (IoT): Sensors and RFID tags deployed in devices enable real-time monitoring and tracking of products and shipments. AI-powered IoT tools effectively analyze this data, identifying and predicting potential issues such as delays or quality problems.

Digital twin: As a virtual replica of physical objects and systems, a digital twin can simulate scenarios such as demand fluctuations or supply disruptions. By providing valuable insights and recommendations, it empowers supply chain managers to make informed decisions.

Businesses that harness the power of ML in their supply chains unlock new levels of intelligence and interconnectedness. These traits pave the way for agile supply chains that leverage data-driven decision-making and effectively tackle disruptions.

Industry 4.0 technologies, with ML and IoT at their core, are increasingly becoming the foundation of global supply chains. As businesses strive for continual improvement, the adoption of these transformative technologies is set to accelerate exponentially in the foreseeable future. Stay ahead of the curve and embrace the power of intelligent supply chains with machine learning!

Conclusion:

The integration of AI and machine learning in supply chain management marks a significant shift in the market. Companies that embrace these technologies gain a competitive edge by streamlining operations, reducing costs, and improving customer satisfaction. The ability to harness data-driven insights, optimize inventory, and enhance collaboration with suppliers positions businesses for success in an increasingly dynamic business landscape. The future of supply chains lies in intelligent systems powered by machine learning, as they enable organizations to navigate disruptions, make informed decisions, and achieve operational excellence.