TL;DR:

- Scientists at the University of Rochester leverage deep learning to enhance X-ray diffraction analysis for materials.

- X-ray diffraction experiments provide vital insights into material structure and properties.

- Conventional analysis methods are time-consuming and contentious.

- Deep learning models, using real-world data, expedite materials innovation and understanding under extreme conditions.

- High-energy-density experiments benefit from this approach.

- Funding from the US Department of Energy and the National Science Foundation supports the project.

- The team aims to promote data sharing to refine their models.

Main AI News:

In the realm of materials science, researchers at the University of Rochester have unveiled an innovative breakthrough, harnessing the power of deep learning to revolutionize the quest for novel materials. Deep learning, they assert, has the potential to elevate an already-established technique, widely regarded as the gold standard for characterizing new materials. In a recent publication in the npj Computational Materials journal, a dynamic interdisciplinary team unveils their groundbreaking models, designed to exploit the wealth of data generated by X-ray diffraction experiments.

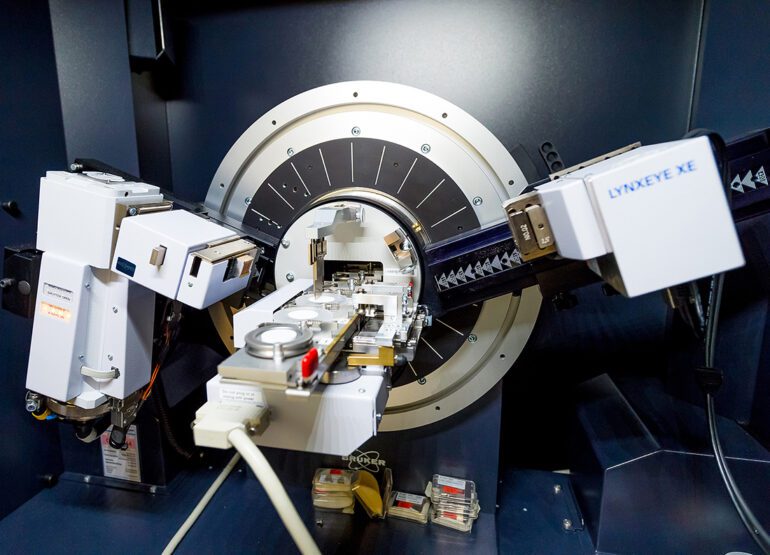

During these X-ray diffraction experiments, powerful lasers illuminate a sample, yielding diffracted images imbued with critical insights into the structure and properties of materials. Niaz Abdolrahim, the visionary leader of the project and an associate professor in the Department of Mechanical Engineering, as well as a distinguished scientist at the Laboratory for Laser Energetics (LLE), underscores the shortcomings of conventional methods used to analyze these images. He emphasizes their contentious nature, time-consuming processes, and frequently underwhelming results.

Abdolrahim elucidates, “Each of these images conceals a wealth of materials science and physics insights, with terabytes of data being generated daily at research facilities and laboratories worldwide. Developing a robust model for data analysis holds the key to expediting materials innovation, comprehending materials under extreme conditions, and advancing materials for diverse technological applications.”

This groundbreaking study, spearheaded by materials science PhD student Jerardo Salgado, exhibits particular promise for high-energy-density experiments, akin to those conducted at LLE by researchers affiliated with the Center for Matter at Atomic Pressures. By precisely monitoring the moment when materials transform phases under extreme conditions, scientists gain invaluable insights into the creation of new materials and the celestial formation of stars and planets.

Abdolrahim elucidates that this pioneering project, generously funded by the US Department of Energy’s National Nuclear Security Administration and the National Science Foundation, surpasses prior attempts to construct machine learning models for X-ray diffraction analysis. Previous endeavors relied predominantly on synthetic data for training and evaluation. In contrast, Abdolrahim, in collaboration with Associate Professor Chenliang Xu from the Department of Computer Science and their dedicated students, incorporated real-world data gleaned from experiments with inorganic materials to refine their deep-learning models.

Yet, Abdolrahim acknowledges that further progress hinges on the availability of additional X-ray diffraction analysis experimental data to refine their models. She reveals the team’s ongoing initiative to establish platforms for data sharing, enabling others to contribute to the system’s training and evaluation, ultimately enhancing its efficacy.

Conclusion:

The integration of deep learning into materials science, as demonstrated by the University of Rochester’s pioneering research, represents a significant advancement in the field. By improving the efficiency and accuracy of X-ray diffraction data analysis, this breakthrough has the potential to accelerate materials innovation and understanding, benefiting industries and applications reliant on materials science research. It underscores the importance of data sharing and collaboration for continued progress in this market.