TL;DR:

- Tata Technologies uses AI/ML to enhance manufacturing processes.

- Achieved an 18% reduction in power consumption.

- Improved process quality, lowered fuel consumption by 10%, and reduced chemical usage by 8%.

- Proactive anomaly detection minimizes shopfloor downtime.

- AI predicts tooling failures, enhancing operational efficiency.

- Tata Technologies is establishing a Center of Excellence for AI technology.

Main AI News:

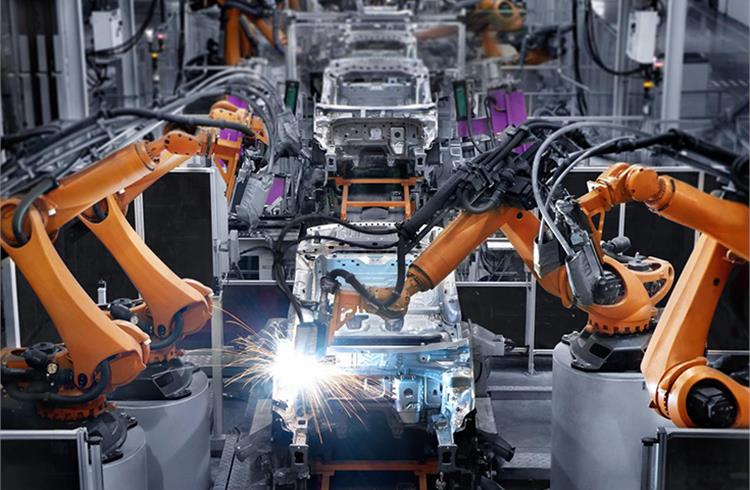

Tata Technologies, a pioneering force in engineering research and development, has been harnessing the potential of artificial intelligence (AI) and machine learning (ML) to revolutionize its manufacturing processes. In a concerted effort to enhance efficiency and environmental responsibility, the company has embarked on a journey that has yielded remarkable results.

Yogesh Deo, Senior VP and Delivery Head of Engineering Research and Development at Tata Technologies, shares insights into their transformative approach. “Essentially, we conducted an in-depth analysis of a year’s worth of process data. Through the strategic deployment of AI and ML models, we achieved an impressive 18 percent reduction in power consumption. Additionally, we observed an enhancement in process quality, a 10 percent reduction in fuel consumption, and an 8 percent decrease in chemical usage,” Deo explained to Autocar Professional.

AI’s pivotal role extends to preemptive anomaly detection, minimizing shopfloor downtime. Deo illustrates this with an example from the paint shop, where the blower system plays a critical role. A single blower malfunction could lead to a complete process halt, entailing repair times of 7-8 hours. “Our approach can be likened to anomaly detection prior to an impending failure or shutdown. We identify anomalies proactively, well before the occurrence of a shutdown or failure. This allows us to swiftly comprehend the issue and take corrective action on the spot,” Deo added.

Furthermore, AI has been instrumental in predictive maintenance for tooling, particularly in dye design. Deo elucidates, “In the realm of dye design, we’ve meticulously analyzed historical operational data to construct a predictive model. This model is then compared with real-time operational data to forecast the dye’s performance. By establishing correlations between operational data and past failure instances, we can determine the remaining useful life of the dye.”

Tata Technologies is not merely dabbling in AI; it is committed to establishing a Center of Excellence for AI technology. Although details remain undisclosed for now, it is evident that the company’s dedication to technological advancement is unwavering.

Conclusion:

Tata Technologies’ strategic adoption of AI and ML has not only led to significant reductions in power consumption and resource usage but has also streamlined manufacturing operations. This commitment to innovation positions the company as a frontrunner in sustainable manufacturing, with the potential to set new industry standards and inspire competitors to follow suit.