TL;DR:

- Tokyo University of Science (TUS) researchers, in collaboration with esteemed institutions, have developed a cutting-edge deep learning model.

- The model, employing 80 convolutional neural networks, can identify icosahedral quasicrystal (i-QC) phases in multiphase powder X-ray diffraction patterns.

- It achieved an impressive accuracy rate exceeding 92% and successfully identified i-QC phases in various materials, even when not the primary constituent.

- The model’s potential extends to identifying new quasicrystals and various crystalline materials.

- This breakthrough promises to expedite phase identification in diverse materials, impacting industries like mesoporous silica, minerals, alloys, and liquid crystals.

Main AI News:

The pursuit of uncovering novel crystalline structures in materials has long been a focal point of scientific inquiry, with far-reaching implications for various industries, including electronics and pharmaceuticals. Crystalline materials, characterized by their meticulously arranged atomic configurations, play a pivotal role in advancing technology. Traditional methods, such as powder X-ray diffraction, have been the go-to approach for precise identification. However, the emergence of multiphase samples, featuring intricate mixtures of different crystalline structures, has presented a formidable challenge.

In response to this challenge, a groundbreaking study conducted by the Tokyo University of Science (TUS), in collaboration with esteemed institutions, has introduced a cutting-edge deep learning model. This research outlines the development of a machine learning-based binary classifier capable of discerning the elusive icosahedral quasicrystal (i-QC) phase amidst complex multiphase powder X-ray diffraction patterns.

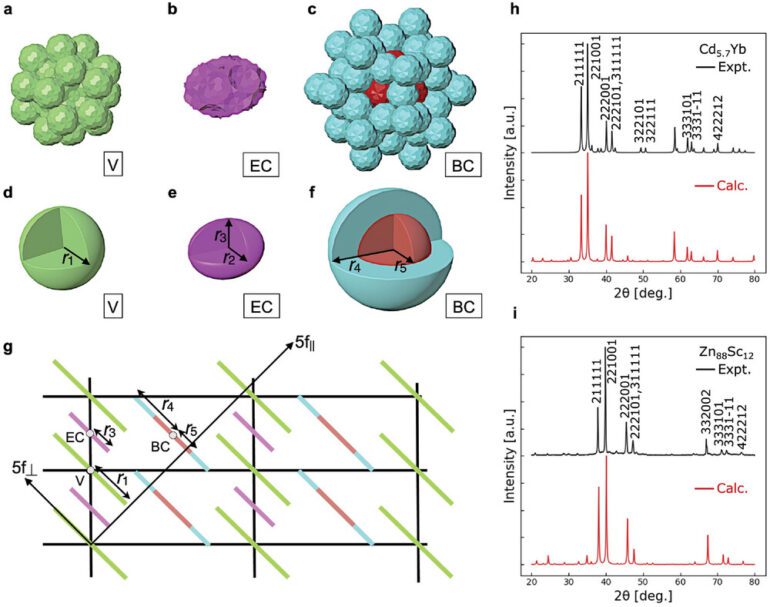

The researchers meticulously crafted a binary classifier, harnessing the power of 80 convolutional neural networks. This sophisticated model underwent rigorous training, utilizing synthetic multiphase X-ray diffraction patterns specifically designed to mimic anticipated i-QC phase patterns. Remarkably, the model exhibited exceptional performance, boasting an accuracy that surpassed the impressive threshold of 92%. It demonstrated its prowess by effectively identifying an unknown i-QC phase within multiphase Al-Si-Ru alloys, scrutinizing a total of 440 measured diffraction patterns sourced from diverse, unidentified materials spanning six alloy systems.

Notably, the model’s capabilities extend beyond the identification of predominant components, as it can successfully pinpoint the elusive i-QC phase even when it is not the primary constituent within the mixture. Furthermore, its potential transcends the realm of i-QC phases, hinting at its applicability in identifying new decagonal and dodecagonal quasicrystals, as well as various other crystalline materials.

This remarkable model promises to significantly expedite the identification process of multiphase samples. The breakthrough, fortified by the model’s remarkable success, stands poised to revolutionize the field of materials science by streamlining phase identification—a critical component in understanding mesoporous silica, minerals, alloys, and liquid crystals.

The profound impact of this study transcends the mere identification of quasicrystalline phases; it heralds a paradigm shift in material analysis. Its potential applications across diverse industrial sectors, from optimizing energy storage to advancing electronics, hold the promise of transformative technological advancements.

Conclusion:

This innovative deep learning model represents a significant advancement in materials science, offering faster and more accurate phase identification capabilities. Its applications span across industries, promising transformative advancements in technology and materials analysis. The market can expect increased efficiency and precision in materials research and development, leading to enhanced product innovations and potentially disruptive technological breakthroughs.