TL;DR:

- Generative AI models like ChatGPT excel at mimicking existing content.

- MIT engineers emphasize the need for AI to go beyond statistical similarity in engineering tasks.

- Standard DGMs often generate designs that mimic existing ones but fall short in engineering performance.

- Task-specific DGMs designed with engineering objectives produce more innovative and high-performing designs.

- AI models could become valuable design partners by focusing on design requirements and performance metrics.

Main AI News:

In the realm of generative AI, models like ChatGPT have dazzled us with their ability to mimic and recreate various forms of content, from poetry to music and visual arts. These AI supermodels excel at generating content that mirrors what they’ve been trained on, making them versatile tools for creative endeavors. However, a recent study from MIT engineers highlights a crucial limitation: similarity alone isn’t enough to foster true innovation in engineering tasks.

Lyle Regenwetter, a mechanical engineering graduate student at MIT and the study’s lead author, points out, “Deep generative models (DGMs) are very promising, but also inherently flawed. The objective of these models is to mimic a dataset. But as engineers and designers, we often don’t want to create a design that’s already out there.”

This study argues that if mechanical engineers seek AI’s assistance in generating novel ideas and designs, they must expand their focus beyond mere “statistical similarity.” Faez Ahmed, co-author and assistant professor of mechanical engineering at MIT, adds, “The performance of a lot of these models is explicitly tied to how statistically similar a generated sample is to what the model has already seen. But in design, being different could be important if you want to innovate.“

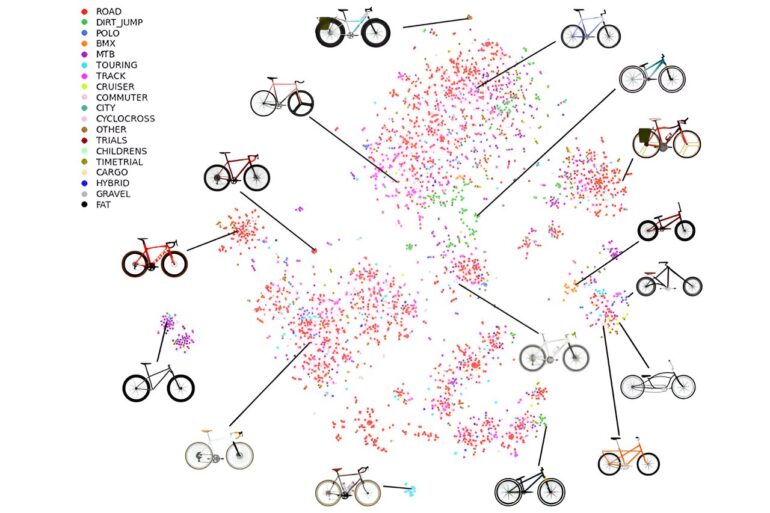

The researchers illustrate the pitfalls of using deep generative models in solving engineering design problems. By examining bicycle frame design, they demonstrate how these models often produce frames that mimic existing ones but fall short in terms of engineering performance and requirements.

However, when the researchers designed DGMs with engineering-specific objectives rather than focusing solely on statistical similarity, the results were striking. These models generated more innovative and higher-performing frames, showing that similarity-focused AI models don’t seamlessly translate to engineering challenges.

As Ahmed emphasizes, “This is about how AI can help engineers be better and faster at creating innovative products. To do that, we have to first understand the requirements. This is one step in that direction.”

The study, conducted in collaboration between computer scientists at MIT-IBM Watson AI Lab and mechanical engineers in MIT’s DeCoDe Lab, has important implications for the future of generative AI in engineering. By acknowledging the need for task-specific metrics and objectives, AI models could become valuable partners in the design process.

The full study is available online now and will be published in the December print edition of the journal Computer-Aided Design. Co-authors of the research include Akash Srivastava and Dan Gutreund at the MIT-IBM Watson AI Lab.

Unlocking the Potential of Generative AI in Engineering

Deep generative models (DGMs) are formidable learners, capable of processing vast datasets and generating content that mimics what they’ve been trained on. These AI models, including ChatGPT and others, have found applications in various engineering domains, from designing aircraft frames to optimizing bridge geometries. However, a critical aspect has been missing from their design process: a focus on design requirements.

DGMs typically aim to generate content that is statistically similar to their training data. While this approach works well for creative tasks, it falls short in engineering, where innovation and performance are paramount. Lyle Regenwetter, a mechanical engineering graduate student at MIT, explains, “Designers who are working with DGMs are sort of missing this cherry on top, which is adjusting the model’s training objective to focus on the design requirements.“

In a case study involving bicycle frame design, MIT researchers highlighted the limitations of conventional DGMs. These models generated frames that resembled existing designs but often failed to meet engineering performance standards. However, when the researchers introduced DGMs specifically designed for engineering tasks, the results were remarkable.

One model, created by Faez Ahmed, prioritized both statistical similarity and functional performance. It produced lighter and stronger bike frame designs but occasionally included physically “invalid” frames due to a lack of design constraints. In contrast, another model designed by Regenwetter, with an emphasis on design constraints and physical feasibility, consistently generated high-performing and physically viable designs.

These findings underscore the potential of AI when explicitly trained for specific design tasks. By incorporating priorities such as performance, design constraints, and novelty, AI models can revolutionize various engineering fields. As Ahmed suggests, this research sheds light on the pitfalls of relying solely on statistical similarity, paving the way for innovative applications of generative AI in engineering beyond multimedia.

Conclusion:

The study underscores the limitations of current generative AI models in engineering design and emphasizes the importance of task-specific training. For the market, this suggests that as AI models evolve to meet engineering requirements, they could become invaluable tools for fostering innovation and efficiency in various engineering domains, potentially revolutionizing the industry.