TL;DR:

- Researchers from U of A and MIT utilize 3D printing and AI to optimize microstructured composites, balancing stiffness and toughness.

- Recent advancements in technology empower researchers to bridge the gap between theoretical predictions and practical outcomes.

- The study highlights the potential of 3D printing in tailoring materials with bespoke mechanical properties.

- An innovative evaluation framework incorporating mechanical testing, prediction, and simulation sets a new standard for computational design.

- Published in Science Advances, the research underscores the robust research ecosystem at U of A and its impact on Arkansas’ economy through education and job development.

Main AI News:

In a remarkable advancement within materials science, scholars from the University of Arkansas (U of A) and the Massachusetts Institute of Technology have pioneered an innovative method to optimize microstructured composites, achieving a delicate balance between stiffness and toughness. This groundbreaking strategy integrates physical experimentation, computational modeling, and the capabilities of artificial intelligence. The equilibrium between stiffness—resistance to deformation, and toughness—energy absorption before fracturing, is paramount for materials utilized in extensive structures such as buildings and bridges.

Navigating Challenges and Achievements

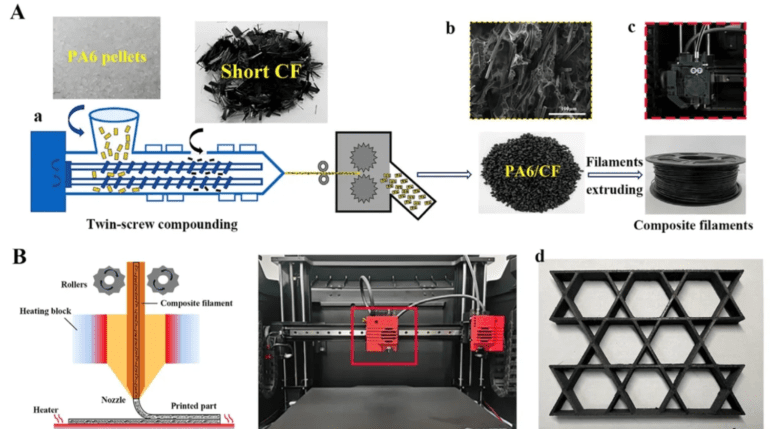

Traditionally, the team encountered discrepancies between theoretical predictions and practical outcomes. Yet, recent strides in 3D printing and computational techniques empowered researchers to delve deeper into microstructured composites, effectively achieving the desired trade-offs between stiffness and toughness. This study highlights the potential of 3D printing technology in tailoring materials with bespoke mechanical properties, broadening its utility across various industrial domains.

Refining the Assessment Process

The study implemented a comprehensive evaluation framework comprising a mechanical tester for precise performance measurements, a predictor for rapid albeit less precise assessments, and an intermediary simulator. This innovative methodology establishes a new standard for computational design, transcending solid mechanics into realms such as polymer chemistry, fluid dynamics, meteorology, and robotics.

Forging a New Frontier in Material Science

Published in Science Advances, a renowned scientific journal, the research underscores the robust research ecosystem at U of A, which significantly bolsters Arkansas’ economy through education, research, and workforce development. This breakthrough signifies a notable milestone in materials science, underscoring the significance of a multidimensional research approach and the transformative potential of 3D printing in advancing industrial applications.

Conclusion:

This groundbreaking research on microstructured composites, leveraging 3D printing and AI, signals a significant advancement in material science. The ability to finely tune mechanical properties opens doors for enhanced performance and innovation across various industrial sectors, promising substantial opportunities for market growth and technological advancement.