TL;DR:

- Researchers from Columbia University and DeepMind have introduced GPAT, a transformer-based model architecture that accurately predicts part poses in assembly tasks.

- GPAT enables autonomous systems to construct novel targets using unseen parts, revolutionizing part assembly with flexibility and adaptability.

- The model approaches part assembly as a goal-conditioned shape rearrangement task, handling diverse part shapes and configurations.

- GPAT employs target segmentation and pose estimation to achieve precise alignment and accurate part assembly.

- GPAT’s capabilities have significant implications for industries such as manufacturing, construction, and logistics.

- It opens doors for the development of robots that can adapt and learn in real time, paving the way for flexible and intelligent automation.

Main AI News:

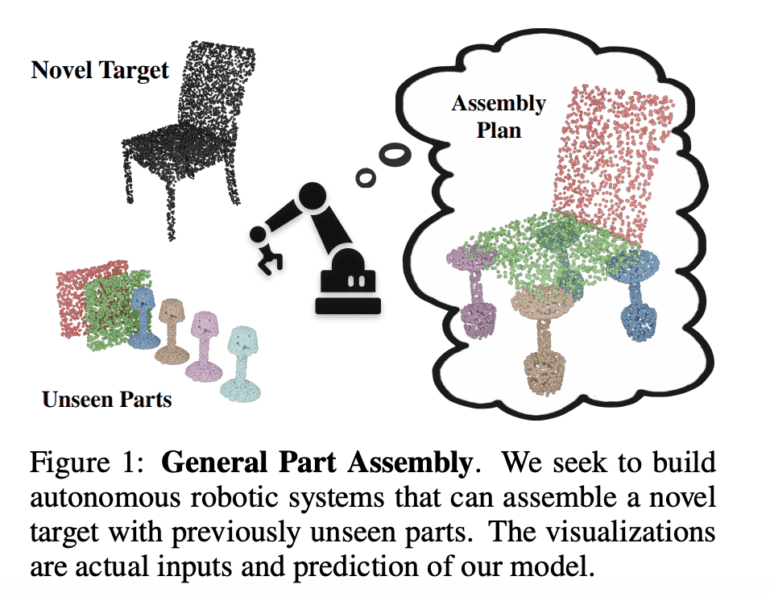

In a groundbreaking collaboration between Columbia University and Google DeepMind, researchers have introduced the General Part Assembly Transformer (GPAT), a transformative model architecture that propels the accuracy of part poses prediction by inferring the correlation between each part shape and the target shape. This development has the potential to unlock a multitude of real-world applications for autonomous robotic systems engaged in visuospatial reasoning and object assembly.

Despite notable strides in part assembly, current methodologies remain constrained by pre-defined targets and familiar categories. To overcome this limitation, the joint research team spearheaded the introduction of GPAT through their remarkable paper entitled “General Part Assembly Planning.” This transformer-based model for assembly planning exhibits exceptional generalization capabilities, empowering it to automatically estimate an extensive array of novel target shapes and parts.

GPAT’s main contributions can be summarized as follows:

- Task of General Part Assembly: The team proposes the concept of general part assembly to evaluate the aptitude of autonomous systems in constructing novel targets using previously unseen parts. By broadening the scope beyond predefined targets, GPAT aims to revolutionize part assembly with unprecedented flexibility and adaptability.

- Goal-Conditioned Shape Rearrangement: To address the planning intricacies associated with general part assembly, GPAT approaches the problem as a goal-conditioned shape rearrangement task. It treats part assembly as an “open-vocabulary” target object segmentation challenge, allowing the model to effectively handle diverse part shapes and configurations.

- Introduction of General Part Assembly Transformer (GPAT): GPAT stands as an innovative transformer-based model meticulously designed for assembly planning purposes. Through its training process, GPAT learns to generalize to various targets and part shapes. The primary objective of this model is to predict a 6-DoF (degree of freedom) part pose for each input part, culminating in a precise and comprehensive part assembly.

The approach employed by GPAT can be outlined as follows:

- Target Segmentation: GPAT initiates its workflow with target segmentation, employing the General Part Assembly Transformer. This initial step dissects the target into distinct segments, representing intricate details of each transformed part. By effectively segmenting the target point cloud, GPAT achieves a profound comprehension of its constituent parts and their spatial relationships.

- Pose Estimation: Following target segmentation, GPAT proceeds to pose estimation, wherein the model leverages the set of parts and segmentations of the target as inputs. By meticulously analyzing this information, GPAT accurately determines the final 6-DoF part poses for each individual part. This precise alignment of parts through pose estimation ensures a successful and impeccable part assembly.

The introduction of GPAT has profound implications for autonomous robotic systems. By harnessing the power of visuospatial reasoning and its ability to generalize to diverse and novel shapes, GPAT holds tremendous promise across various industries, including manufacturing, construction, and logistics. The efficiency and accuracy afforded by GPAT enable autonomous systems to proficiently assemble objects with previously unseen parts, unlocking new frontiers of automation.

Conclusion:

The introduction of GPAT and its advanced transformer-based model architecture represents a significant breakthrough in the field of autonomous part assembly. Its ability to accurately predict part poses and handle diverse shapes brings unparalleled flexibility and adaptability to the market. Industries such as manufacturing, construction, and logistics can leverage GPAT to streamline assembly processes, improve efficiency, and unlock new possibilities for automation. The generalization capabilities of GPAT lay the foundation for developing robots that can dynamically adapt to complex assembly tasks, setting the stage for a new era of intelligent and flexible automation solutions.