- Scan & Sew integrates 3D/AI tech with upholstery craftsmanship for boat covers.

- Their technology simplifies pattern creation from uploaded photos, reducing production times.

- Benefits include increased efficiency, reduced order backlogs, and potential cost savings.

- Logistics are streamlined, minimizing vessel downtime during the scanning process.

- Partnership opportunities are easily accessible through their website for seamless integration.

Main AI News:

Scan & Sew, renowned for its fusion of advanced 3D/AI technology with traditional upholstery craftsmanship, announces a groundbreaking solution tailored for boat cover production. This innovative approach promises to propel boat cover businesses into a new era of efficiency and profitability.

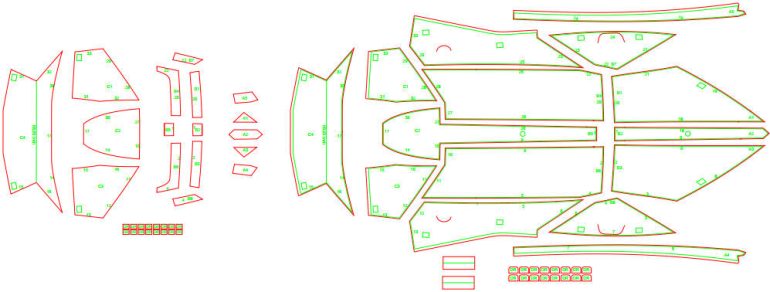

At the heart of Scan & Sew’s offering is its pioneering 3D Modeling & Design technology, designed to streamline every facet of the production process. Upholstery shops specializing in boat covers can now leverage this technology to achieve remarkable operational efficiencies. By simply uploading photographs, Scan & Sew transforms them into precise 3D models and generates meticulously crafted cover patterns. This transformative capability not only accelerates pattern creation but also slashes production times, enabling shops to meet increased demand without compromising on quality.

“Scan & Sew’s technology is a game-changer for boat cover businesses,” remarks a spokesperson. “It allows them to manage larger order volumes, reduce production backlogs, and ultimately, deliver superior customer satisfaction with unprecedented speed and precision.“

Key advantages of integrating Scan & Sew’s technology include:

- Increased Efficiency: Rapid pattern creation translates to faster production cycles and shorter delivery times, empowering shops to handle more orders seamlessly.

- Reduced Backlogs: By optimizing production workflows, Scan & Sew helps shops effectively manage and diminish order backlogs, ensuring timely delivery and customer satisfaction.

- Cost Savings: The adoption of Scan & Sew’s technology proves more cost-effective compared to traditional design and cutting methods, making it a financially prudent choice for forward-thinking businesses.

Additionally, the logistical ease provided by Scan & Sew further enhances operational fluidity. Shops no longer require extended vessel access; instead, they can efficiently complete the scanning process in minimal time, expediting service delivery without disruption.

“Partnering with Scan & Sew is more than just adopting technology; it’s about setting new industry standards,” emphasizes the spokesperson. “Our seamless online partnership sign-up process ensures that shops can swiftly integrate our solutions into their operations, unlocking unparalleled efficiencies and positioning themselves as leaders in the market.”

With Scan & Sew, boat cover upholstery shops not only enhance their operational capabilities but also elevate customer satisfaction levels through prompt service and superior quality. As the industry embraces digital transformation, Scan & Sew stands at the forefront, empowering businesses to thrive in a competitive landscape with innovation and reliability.

Conclusion:

Scan & Sew’s innovative approach to integrating 3D/AI technology with traditional upholstery craftsmanship represents a significant advancement for the boat cover production market. By enabling faster production cycles, reducing backlogs, and offering cost-effective solutions, Scan & Sew empowers upholstery shops to meet growing demand efficiently. This technological leap not only improves operational efficiency but also sets a new standard for service delivery in the industry, ensuring enhanced customer satisfaction and market leadership.