TL;DR:

- Senvol’s machine learning (ML) approach revolutionizes material allowables in additive manufacturing.

- ML software accurately predicts material performance, enhancing efficiency and cost-effectiveness.

- Senvol’s success stemmed from collaborative efforts with industry partners and technical advisors.

- Traditional material allowables development hurdles to be overcome through adaptable ML-driven methodology.

- Senvol’s ML software optimizes data generation and can be applied across diverse processes and materials.

- Industry-wide shift towards AI and ML software in additive manufacturing is evident, propelling efficiency and success rates.

Main AI News:

In the realm of additive manufacturing, Senvol, a trailblazer in additive manufacturing data, has unveiled a pioneering machine learning (ML) approach that promises to reshape the landscape of material allowables. Their ML software has astutely predicted material performance, marking a significant advancement in this intricate domain.

The convergence of Senvol’s expertise and technological prowess has been harnessed in the realization of this groundbreaking approach. Tasked with the mission to expedite the development of material property allowables for additive manufacturing, Senvol deployed its machine learning software, Senvol ML, to remarkable effect. Notably, this achievement unfolded under the aegis of a prestigious US Government contract, W911NF-20-9-0009.

Distinguished by its cost-efficiency, flexibility, and timeliness, Senvol’s methodology eclipses the conventional Metallic Materials Properties Development and Standardization (MMPDS) avenue for material allowables development. This heralds a new era propelled by the fusion of machine learning with material science ingenuity.

Collaborative synergy was paramount to Senvol’s triumph. Joining forces with EWI and Pilgrim Consulting, the program bore testimony to the prowess of strategic partnerships. The intellectual guidance provided by Battelle and Lockheed Martin’s LM Fellow, Hector Sandoval, lent a profound technical dimension. This concerted effort was overseen by the National Center for Manufacturing Sciences (NCMS) through the AMMP Other Transaction Agreement (OTA) program.

Annie Wang, President of Senvol, affirms the game-changing nature of this achievement, stating, “Material allowables development is a very expensive and time-consuming endeavor… leverages machine learning. We were very pleased with the results and look forward to continued work in this cutting edge area.“

Dr. William E. Frazier, a luminary in the field, underscores the strategic significance: “Senvol’s machine learning-enabled approach directly addresses a major industry challenge: the rapid and cost-effective development of additive manufacturing material property allowables.”

Pioneering Unprecedented Efficiency with ML

The potential of additive manufacturing is hindered by the onerous demands of allowables development. Senvol’s methodology addresses this obstacle, ushering in newfound efficiency. Traditionally, the resource-intensive nature of generating empirical data at a fixed processing point has rendered allowables development an expensive endeavor. The advent of Senvol’s machine learning-driven approach transforms this landscape.

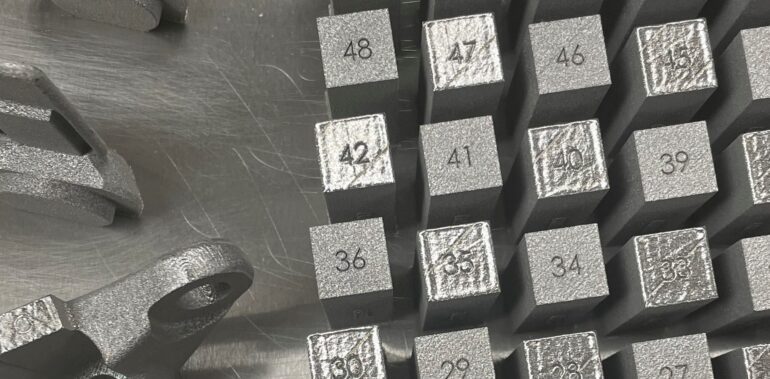

Senvol’s program spotlighted a specific material, 17-4 PH Stainless Steel, processed through a powder bed fusion 3D printer. The dynamic capabilities of Senvol’s ML software, designed to qualify additive manufacturing processes, facilitated the development of statistically substantiated material properties. Remarkably, this achievement was realized while optimizing data generation requisites.

Senvol’s machine learning paradigm transcends boundaries, adapting seamlessly to diverse additive manufacturing processes, printers, and materials. This adaptability bodes well for sustainable, long-term progress.

Looking Ahead: A Promising Trajectory

As the realm of additive manufacturing continues its transformative journey, Senvol’s achievements stand as a beacon of innovation. While machine learning has become a staple in additive manufacturing processes, Senvol’s groundbreaking approach to material allowables development stands as a testament to their pioneering spirit.

Zach Simkin, President of Senvol, acknowledges the journey ahead: “The upside is tremendous, and we look forward to continuing to partner with the Government and industry to advance work in this area.“

It’s imperative to note that while the project did not yield absolute allowables, budget constraints and programmatic considerations underscore the challenges encountered. The trajectory of AI and ML software in additive manufacturing holds enormous potential. As exemplified by Ai Build’s success and AON3D’s thermal optimization software, machine learning’s transformative impact continues to reshape the industry’s landscape.

Conclusion:

In the dynamic landscape of additive manufacturing, Senvol’s groundbreaking ML-driven approach to material allowables signifies a monumental stride. The successful application of machine learning not only elevates efficiency and cost-effectiveness but also underscores the industry’s readiness to embrace transformative technologies. As AI and ML integration gains momentum, the additive manufacturing market can anticipate heightened productivity and a future characterized by streamlined processes and higher success rates.