TL;DR:

- Siemens Digital Industries Software introduces an IC design and verification solution enabled by assistive AI technology.

- The Solido Design Environment software addresses challenges in complex circuit design for wireless, automotive, HPC, and IoT applications.

- AI-driven optimization paths enhance circuit power, performance, and area, while reducing runtime for statistical yield analysis.

- The software achieves verification accuracy up to 6 sigma and significantly improves coverage and accuracy.

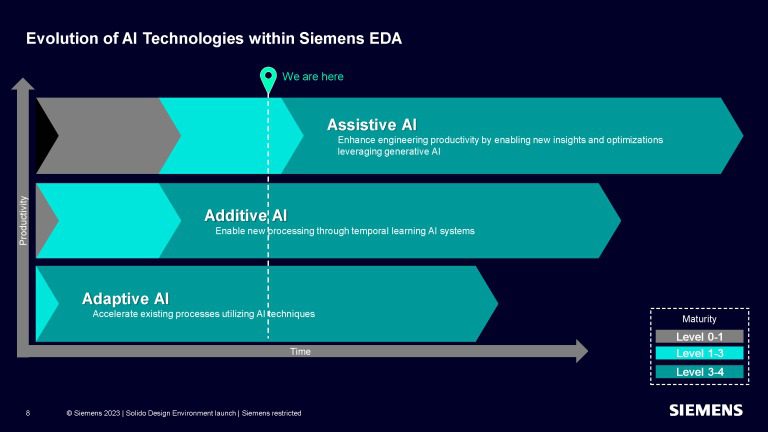

- Siemens aims to lead the EDA market with adaptive AI, additive AI, and assistive AI at various stages of readiness.

- Early customers, including SK hynix and Forza Silicon, have experienced substantial benefits, reducing design-to-production time.

Main AI News:

Siemens Digital Industries Software has unveiled a groundbreaking integrated circuit (IC) design and verification solution, marking a significant step in their roadmap to harness the power of assistive AI (artificial intelligence). This cutting-edge technology aims to empower design teams by surpassing aggressive power, performance, yield, and reliability targets while simultaneously expediting time-to-market.

The Solido Design Environment software, their latest innovation, is specifically crafted to tackle the challenges posed by increasing design complexity across various applications, including wireless, automotive, high-performance computing (HPC), and the Internet of Things (IoT). A notable feature of this software is the provision of a unified, comprehensive cockpit, which efficiently manages nominal and variation-aware analysis. This encompasses SPICE-level circuit simulation setup, measurements and regressions, waveforms, and statistical results analysis.

Leveraging the potential of AI, Solido is capable of guiding users toward optimization paths that enhance circuit power, performance, and area. Additionally, it enables production-accurate statistical yield analysis, dramatically reducing runtime when compared to brute-force methods. Furthermore, the software incorporates state-of-the-art additive learning technology, enhancing performance for design and verification teams. This results in faster and smarter AI decisions and analysis, facilitated by the retention of AI models. With such advanced capabilities, Solido assists in achieving verification accuracy of up to 6 sigma, yielding speeds that are orders of magnitude faster than brute-force Monte Carlo methods. Moreover, it substantially augments coverage and accuracy.

In a recent interview with embedded.com, Amit Gupta, Vice President, and General Manager of the Custom IC Verification Division at Siemens Digital Industries Software, elaborated on the roadmap for AI in Electronic Design Automation (EDA). He explained the different levels of AI integration, ranging from adaptive AI to additive AI and assistive AI, each contributing at various stages of readiness. Gupta emphasized that the key attributes of AI in EDA encompass verifiability, usability, generality, robustness, and accuracy. Usability, in particular, refers to the absence of a requirement for algorithm expertise, while generality ensures it functions across any system. Furthermore, robustness guarantees resilience in case of unexpected issues.

As engineering teams grapple with the growing complexities of design and increasing variation effects, they must meet demanding targets for power, performance, area, and yield. To address these challenges head-on, the Solido Design Environment software offers cutting-edge AI technology for signoff variation analysis. Seamlessly integrated into an intelligent, cloud-ready design environment, Solido provides game-changing advantages for custom IC design. It extends its benefits to standard cell, memory, and analog IP design teams.

Gupta proudly shared that Solido already boasts a vast user base, with numerous early customers reaping significant rewards. For instance, SK hynix Inc., renowned for advanced memory and sensor technologies, reported a noteworthy reduction in the time it takes to transition from initial design to production. Mr. Do Chang-Ho, Head of Computer-Aided Engineering at SK hynix, highlighted the importance of verification accuracy and turnaround time in their design flow. Siemens’ Solido Design Environment delivered accurate variation analysis, coupled with powerful and user-friendly design optimization, leading to impressive time savings.

Sam Bagwell, Director of US Design Services for Forza Silicon (AMETEK, Inc.), also praised the software’s impact. Their designers rely on Solido Design Environment for simulating state-of-the-art, low-noise, high-resolution, ultra-high-speed CMOS image sensors for diverse applications, including cinematography, machine vision, automotive, AR/VR, and more. The solution has proven to be an outstanding asset, boosting productivity with efficient design workflows, intuitive results visualization, and exceptional user support.

Conclusion:

Siemens’ launch of an advanced AI solution for IC design and verification represents a significant development in the semiconductor market. By leveraging AI technology to address complex design challenges and optimize circuit performance, Siemens aims to enhance the efficiency of design teams and accelerate time-to-market for cutting-edge semiconductor products. The adoption of adaptive AI, additive AI, and assistive AI in Electronic Design Automation (EDA) will likely shape the future of IC design, revolutionizing the industry and providing competitive advantages to early adopters. As more companies embrace this technology, we can expect increased competition and innovation in the semiconductor market, ultimately driving further advancements and breakthroughs in the field.