TL;DR:

- Supply chain forecasting is crucial for businesses, and traditional methods are becoming outdated.

- Machine learning algorithms offer a game-changing solution by analyzing vast amounts of data and generating highly accurate demand forecasts.

- Micro-forecasting allows businesses to make predictions at a granular level, optimizing inventory management and improving product availability.

- Implementing machine learning forecasting requires integrating AI systems, ensuring data quality, and building trust among staff and customers.

- AI technology reshapes the way businesses operate and engage with customers, allowing them to respond nimbly to market changes.

- The future of supply chain forecasting lies in advanced AI algorithms integrating factors like social media trends and customer sentiment.

Main AI News:

Revolutionizing Supply Chain Forecasting: The Power of Machine Learning

Imagine the consequences of a single forecasting mistake reverberating throughout the entire supply chain—surplus inventory, strained supplier relationships, and disappointed customers. In today’s fast-paced world, accurate supply chain forecasting has become more critical than ever before.

Traditional methods like moving averages and exponential smoothing, once relied upon by businesses, are showing signs of age. They struggle to keep up with rapidly changing market conditions and the increasing complexity of supply chain networks. However, there is a game-changing solution on the horizon—machine learning. As a subset of artificial intelligence, machine learning enables businesses to transcend outdated methods and transform their operations.

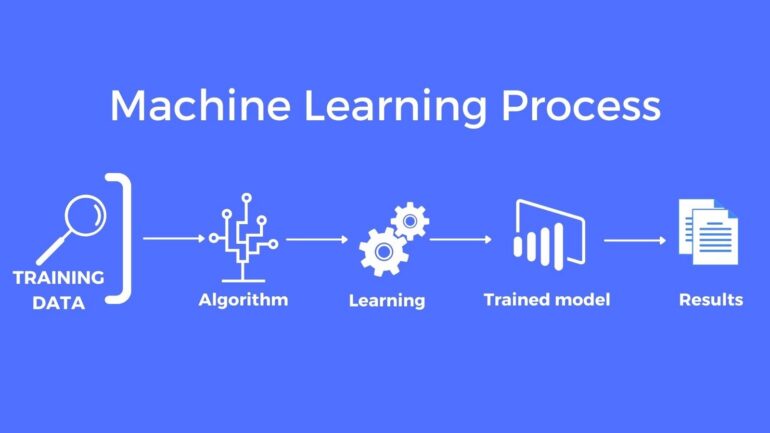

While machine learning algorithms may initially appear complex, understanding their mechanics and applications is well within reach. These algorithms analyze vast amounts of data, identify patterns, and provide accurate predictions. By considering historical sales, market trends, and external influences such as weather patterns or economic indicators, machine learning algorithms generate highly precise demand forecasts.

Let’s consider an example: an online pet supply company seeking to optimize its inventory. By employing machine learning algorithms, the company can identify patterns where sales of certain dog food brands tend to spike during specific seasons, such as increased demand for grain-free options during allergy season. Additionally, these algorithms can recognize that promotional events like National Pet Day often lead to an increased demand for pet toys and accessories. They can even factor in potential disruptions in the supply chain, such as delayed shipments due to extreme weather conditions or global supply chain issues.

Through continuous learning from these data points and understanding the intricate relationships between them, machine learning algorithms generate highly accurate demand forecasts for the pet supply company. Consequently, the company can stock the right amount of pet food and other products, minimize waste from expired items, and avoid stockouts, all while ensuring customer satisfaction.

Embracing Granular Demand Predictions

Machine learning algorithms not only improve traditional forecasting methods but also enable a revolutionary approach known as micro-forecasting. This method involves making predictions at a more granular level, such as individual stores, sales channels, or specific product categories. The implications of micro-forecasting are far-reaching, allowing businesses to fine-tune inventory management and enhance product availability for their customers.

Micro-forecasting empowers businesses to make informed decisions regarding inventory allocation, pricing strategies, and targeted promotions by gaining a deeper understanding of customer demand at a granular level. Furthermore, it enables supply chain leaders to identify and respond to market trends, demographic shifts, and local events more effectively.

Consider a consumer electronics retailer like Best Buy, leveraging AI to predict store-specific demand for a popular gaming console during the holiday season. By analyzing granular data, such as historical sales of similar products, the retailer can predict not only the overall demand but also variations across different store locations and customer segments.

With this valuable information, the retailer can optimize inventory levels for each store, ensuring locations with higher demand receive adequate stock while preventing excess inventory buildup in locations with lower demand. Additionally, the retailer can adjust pricing and promotional strategies to better target specific customer segments and capitalize on local market conditions. Ultimately, this results in a significant reduction in stockouts, increased sales, and improved customer satisfaction during the holiday season.

Implementing Machine Learning Forecasting

While machine learning forecasting offers numerous benefits, it does come with its fair share of challenges and considerations. One significant challenge is integrating AI systems into existing infrastructures, particularly when it requires seamless interoperability between different software platforms. Businesses must thoroughly examine their current systems and work towards a smooth integration that ensures maximum efficiency.

The quality and accessibility of data also play a crucial role in the success of machine learning forecasting. Data sources such as historical sales, real-time market trends, and external factors like weather patterns are vital in generating accurate predictions. However, if the data is of poor quality, inconsistent, or difficult to access, the effectiveness of forecasting can be significantly compromised. Businesses must invest in robust data management practices to fully leverage AI-driven forecasting.

Although technological challenges exist, they must not overshadow the need to build trust in AI-driven predictions among both staff and customers. Businesses can achieve this by fostering a culture of transparency, ensuring that employees understand the benefits and limitations of machine learning forecasting. For instance, conducting training sessions on AI applications and sharing insights on AI-generated predictions can help employees become more comfortable with the technology. Additionally, proactive communication with customers about the ethical and responsible use of AI practices, including data privacy and security measures, builds confidence in the technology.

Embracing the Future

AI has already made remarkable strides in streamlining inventory management, reducing carrying costs, and minimizing stockouts. However, its true transformative potential lies in reshaping the way businesses operate and engage with their customers.

AI forecasting enables companies to respond more nimbly to market changes and better anticipate their customers’ shifting expectations. In this way, AI technology not only revolutionizes supply chain operations but also reshapes the relationships that businesses cultivate with their customers.

As AI continues to evolve, we can envision a future where forecasting algorithms integrate a wider array of factors, including social media trends, customer sentiment, and geopolitical events. This advanced level of precision will empower businesses to make even more informed decisions in an ever-changing marketplace.

To truly capitalize on the benefits of AI-powered forecasting, businesses must invest in understanding the technology, develop effective data management strategies, and address the challenges of internal buy-in and trust. Technological challenges should not overshadow the importance of fostering a culture of transparency among both staff and customers.

Ultimately, the impact of machine learning on supply chain forecasting will be profound and far-reaching, offering businesses a powerful instrument to enhance operations and better serve their customers. By delving into the mechanics of machine learning algorithms, embracing micro-forecasting, and overcoming implementation challenges, business leaders can unlock the full potential of AI-driven forecasting. The future of supply chain forecasting is intricately tied to the continued advancement of machine learning, and those who embrace this technology will be best prepared to adapt and flourish.

Conclusion:

The revolution brought about by machine learning in supply chain forecasting has significant implications for the market. Businesses that embrace this technology gain a competitive edge by accurately predicting demand, optimizing inventory, and enhancing customer satisfaction. The ability to leverage granular forecasts enables targeted decision-making, such as pricing strategies and promotions. However, successful implementation requires addressing technological challenges, ensuring data quality, and fostering transparency.

As AI continues to evolve, forecasting algorithms integrating additional factors will provide businesses with unparalleled precision, empowering them to make informed decisions in an ever-changing marketplace. Those who embrace and adapt to this transformative technology will be well-positioned to thrive in the future market landscape.