TL;DR:

- Machine learning (ML) is revolutionizing the semiconductor industry, offering benefits in predictive maintenance, defect detection, and process control.

- ML algorithms are being developed and implemented to effectively analyze vast amounts of data in the semiconductor industry.

- ML tasks in semiconductors include classification, predicting material properties, device performance, and manufacturing processes.

- ML models can predict macroscopic and microscopic properties based on data about each atom.

- Automatic defect classification (ADC) methods using ML and convolutional neural networks (CNN) can detect microchip imperfections with high accuracy.

- Limitations of ML in the semiconductor industry include inadequate statistical analysis and a need for more testing in real-world production.

- An extensible input data-based approach with explainable AI (XAI) can enhance yield prediction in semiconductor manufacturing.

- AI can help address supply chain bottlenecks, improve chip quality, and optimize production capacity.

- Genetic algorithms (GA) combined with decision tree classifiers can predict failure outcomes based on failure descriptions.

- The implementation of AI/ML in the semiconductor industry has the potential to create significant commercial value, and companies should invest in AI/ML strategies to stay competitive.

Main AI News:

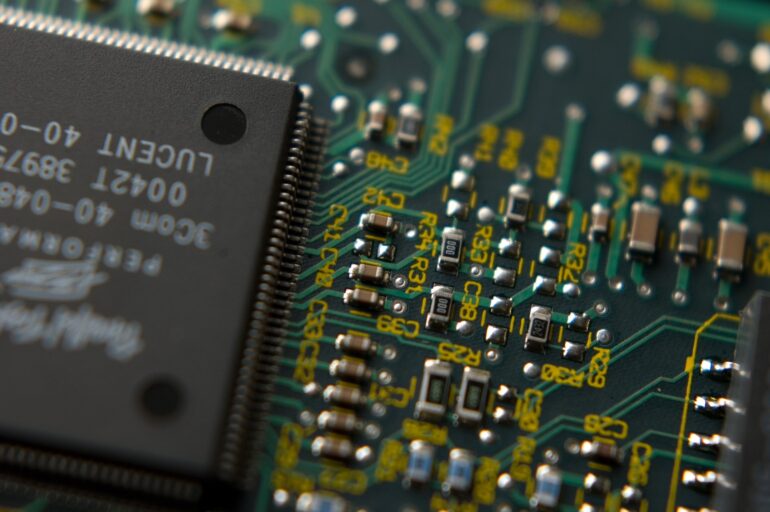

The implementation of machine learning (ML) in the semiconductor industry has revolutionized the way businesses operate, offering tremendous benefits in predictive maintenance, defect detection, and process control. An in-depth analysis published in the esteemed journal Chip sheds light on the pivotal role played by ML in data analysis within this industry.

Semiconductor researchers and experts in material analysis and fabrication have embarked on a relentless pursuit to develop and deploy cutting-edge ML algorithms. These algorithms effectively harness the vast amounts of data available, enabling accurate predictions and informed decision-making. According to the article, ML tasks in the semiconductor realm predominantly revolve around classification, predicting material properties, device performance, and optimizing manufacturing processes. Consequently, the majority of ML applications in this field rely heavily on supervised learning techniques.

The implementation of ML in semiconductor research can be categorized into two distinct avenues. The first involves the development of data models that capture macroscopic information about the materials, such as lattice constants, space groups, and elastic modulus. Additionally, ML techniques are utilized to determine the precise position and type of every atom, facilitating the prediction of both macroscopic and microscopic properties. Noteworthy examples of such models include machine-learning interatomic potentials (MLIP) and machine-learning force fields (MLFF).

To address the issue of microchip imperfections, investigators have introduced an automatic defect classification (ADC) method. By leveraging a convolutional neural network (CNN) approach, this system can detect defects in semiconductor chips with remarkable accuracy, significantly reducing the need for human intervention. The effectiveness of this method has been demonstrated through rigorous experimentation, showcasing its potential to streamline quality control processes.

Despite the remarkable advancements, it is crucial to acknowledge the limitations of ML in the semiconductor industry. Insufficient statistical analysis poses a significant challenge, as the abundance of data does not always translate into effective ML models. The level of generality in a model directly correlates with the amount of training data required to develop an accurate and robust model. Achieving the right balance between abstraction and data availability is essential for achieving optimal ML outcomes.

Furthermore, rigorous testing within actual simulation and production environments remains an area that demands attention. While conceptualization and confirmation stages are predominant in current research efforts, there is a pressing need to bridge the gap and facilitate real-world implementation. The semiconductor industry must strive to conduct comprehensive testing and validation to ensure the seamless integration of ML methodologies.

Expanding the Horizons: AI-Driven Yield Prediction

The manufacturing of semiconductor devices involves a myriad of intricate operations influenced by various factors. Addressing this complexity, a groundbreaking study published in Applied Sciences presents an innovative approach that employs extensive input data and explainable artificial intelligence (XAI) to enhance yield prediction.

The study extensively compares and optimizes ten distinct machine learning algorithms to identify the data prediction model with the highest performance. Remarkably, the selected RF model showcases significantly improved prediction scores, boasting a mean absolute error of 0.520 and a root mean square error of 0.648. These findings hold immense implications for boosting production yields across diverse manufacturing processes.

AI’s Role in Overcoming Supply Chain Bottlenecks and Ensuring Chip Quality

The International Journal of Research Publication and Reviews highlights the transformative potential of AI in addressing critical challenges in semiconductor manufacturing. By harnessing real-time data from existing datasets, businesses can construct robust machine learning models, enabling them to make informed decisions based on actual data rather than mere assumptions. This approach enhances the precision of forecasts and empowers companies to proactively respond to client demands, optimize production capacity, and eliminate bottlenecks.

Moreover, AI offers a promising solution to combat product quality issues arising from limitations in current testing and visual inspection procedures. Traditionally, human-dependent methods, including manual inspections, have prolonged manufacturing cycles and escalated costs. To overcome these hurdles, the proposed AI-based solution relies on historical data sources to train an artificial neural network ML model. Coupled with an image processing algorithm, this flexible decision-assisting tool enhances product inspections by utilizing dynamic reference photos for accurate comparisons. By employing the segmentation of colors, even the slightest defects in semiconductor chips can be readily detected.

A Genetic Algorithm Unveiling Root Cause Failures

Scientific Reports presents a groundbreaking article aiming to develop a model capable of predicting failure outcomes by analyzing distinct failure descriptions. Leveraging the power of genetic algorithms (GA), a subset of artificial intelligence, this research simulates the process of natural selection, allowing for effective search operations in complex environments. The article introduces GA-DT, an amalgamation of a genetic algorithm and a decision tree classifier, which demonstrates remarkable accuracy in predicting failure outcomes. By preprocessing failure analysis descriptions, employing word vectorization techniques, and utilizing GA variable selection alongside supervised learning, the proposed model showcases the potential to accurately prognosticate failure processes.

Market Analysis: Seizing the AI/ML Opportunity

According to a report published by McKinsey and Company, the application of AI/ML presents a unique opportunity for semiconductor organizations to unlock substantial commercial value. While AI/ML currently contributes between $5 and $8 billion in annual revenue, this figure represents only a fraction of its maximum industry value. Projections suggest that within the next two to three years, AI/ML could generate an astonishing $35 billion to $40 billion. This analysis underscores the critical importance for semiconductor companies to allocate significant resources toward AI/ML strategies to remain competitive and avoid being left behind in this rapidly evolving landscape.

Conlcusion:

The integration of machine learning and artificial intelligence in the semiconductor industry holds immense potential for market growth and competitiveness. By leveraging advanced ML algorithms, businesses can improve predictive maintenance, defect detection, and process control, leading to enhanced product quality and operational efficiency.

Furthermore, the utilization of AI-driven yield prediction, supply chain optimization, and chip quality enhancement techniques enables organizations to unlock significant commercial value. To remain at the forefront of the market and capitalize on these opportunities, semiconductor companies must embrace AI/ML strategies and allocate substantial resources towards their implementation. By doing so, they can position themselves for success in an industry poised for exponential growth and transformation.