TL;DR:

- Figure and BMW strike a “commercial agreement” for the deployment of a humanoid robot.

- Initial deployment involves five specific manufacturing tasks, with the potential for expansion.

- The partnership reflects a trend in specialized robotics systems evolving into multi-purpose solutions.

- Applications include box handling, pick-and-place operations, and pallet loading/unloading.

- Figure aims to release its first commercial robot within a year, emphasizing rapid innovation.

- Collaboration with early partners like BMW influences the choice of initial applications.

- Figure focuses on creating dexterous, human-like hands for manipulation, and optimizing workspace compatibility.

- Leg functionality is deemed crucial for maneuvering during specific tasks.

- Training utilizes reinforcement learning, simulation, and teleoperation for real-world adaptability.

- Long-term integration into BMW’s production line depends on meeting internal productivity benchmarks.

- Figure offers robots through Robotics as a Service (RaaS) as a sustainable business model.

Main AI News:

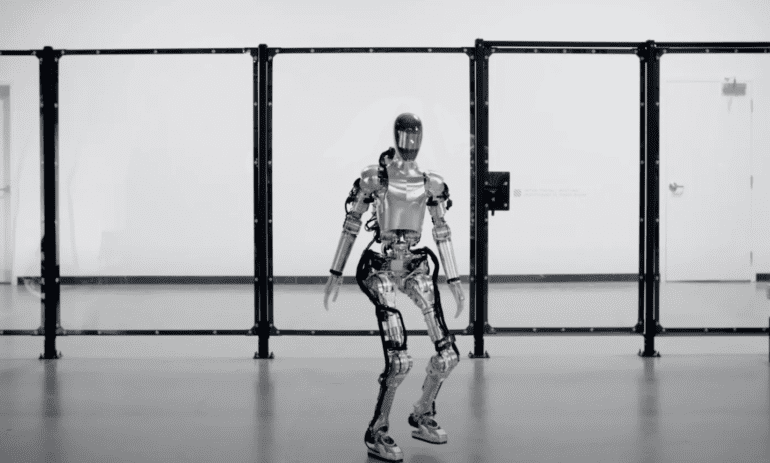

In a strategic move, Figure has unveiled a groundbreaking “commercial agreement” that paves the way for its inaugural humanoid robot to join the BMW manufacturing facility in South Carolina. Notably, the Spartanburg plant stands as BMW’s exclusive production site in the United States, a testament to the automaker’s commitment to quality and innovation. This collaboration signifies a significant leap forward in the realm of automotive manufacturing, marrying cutting-edge robotics with the precision and excellence BMW is renowned for.

While specific details regarding the quantity of Figure 01 models to be initially deployed and the precise roles they will undertake remain undisclosed, Figure has confirmed that the robot’s integration will commence with a series of five distinct tasks, each rolled out sequentially. This measured approach aligns with the evolving landscape of robotics, where systems start as specialized entities and progressively expand their skillsets, much like apps in an app store. Boston Dynamics’ Spot robot, for instance, follows a similar trajectory via its Software Development Kit (SDK).

The initial applications for Figure’s humanoid robot are poised to include fundamental manufacturing functions such as box handling, pick-and-place operations, and pallet loading and unloading—tasks that have historically posed challenges in retaining human workers due to their repetitive nature. Figure CEO Brett Adcock anticipates the debut of their first commercial robot within a year, exemplifying the company’s commitment to swift innovation.

The selection of these inaugural applications will be heavily influenced by Figure’s early collaborators, including BMW, with a focus on tasks requiring exceptional dexterity. Moreover, Figure has secured additional clients, although their identities remain confidential for now, suggesting that the company may unveil them individually over the next 12 months to maintain momentum and anticipation.

Unlike some other humanoid robotics designers, such as Agility, Figure’s primary emphasis lies in crafting a dexterous, human-like hand for manipulation. This design philosophy aligns with the rationale behind the humanoid form factor: optimizing workspaces tailored to human environments. Adcock alludes to Figure 01’s initial responsibilities, which necessitate a high degree of dexterity.

Regarding the importance of legs, Figure maintains that their significance transcends merely walking up stairs or navigating uneven terrain. Leg functionality plays a pivotal role in maneuvering during specific tasks, a crucial consideration in the grander scheme of humanoid robot development.

The training regimen for Figure 01 encompasses a blend of techniques, including reinforcement learning, simulation, and teleoperation to assist the robot in navigating challenging scenarios. Like humans, the robot will learn on the job and refine its capabilities during real-world testing. The long-term integration of these systems into the BMW production line hinges on their ability to meet the automaker’s internal productivity benchmarks. In the interim, Figure will continue to offer these robots through Robotics as a Service (RaaS), a sustainable model poised to shape the future of robotics in manufacturing.

Conclusion:

BMW’s partnership with Figure to integrate humanoid robots signifies a significant shift in the automotive manufacturing sector. This move aligns with the trend of specialized robotics systems evolving into multi-purpose solutions, potentially revolutionizing manufacturing processes. The emphasis on dexterity and adaptability in these robots demonstrates a commitment to enhancing efficiency and productivity in the industry.