TL;DR:

- Circu Li-ion’s upcycling machine swiftly diagnoses battery health, distinguishing between reusable and non-reusable cells.

- The machine employs AI and a battery library to visually identify and separate cells from other materials.

- Usable cells are repurposed for mobility or renewable energy storage, reducing waste.

- Traditional recycling methods often result in the loss of valuable materials.

- The machine uses Electrochemical Impedance Spectroscopy to assess cell health with remarkable accuracy.

- Circu Li-ion charges manufacturers and recyclers for machine and software usage.

- Recent funding of $9 million will support scaling their machine-as-a-service model and data repository.

Main AI News:

In a world dominated by technological advancements, the challenge of disposing of batteries responsibly has grown exponentially. Circu Li-ion, a pioneering startup based in Luxembourg, has emerged as a game-changer in the battery recycling industry. Their groundbreaking upcycling machine is poised to transform the way we view battery disposal.

Circu Li-ion’s co-founder and CEO, Antoine Welter, proudly declares that their innovative machine can swiftly diagnose batteries, distinguishing the reusable from the obsolete in a matter of seconds. “We know exactly which cell can be reused and which one can’t,” he confidently stated.

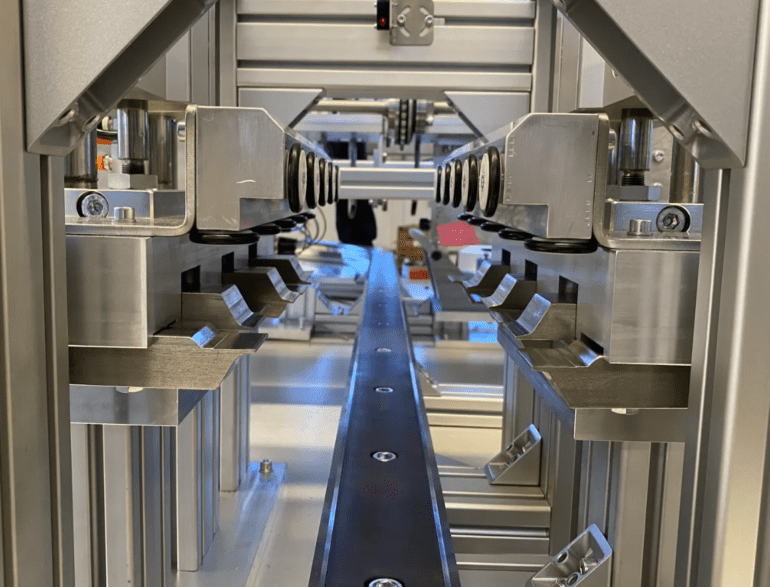

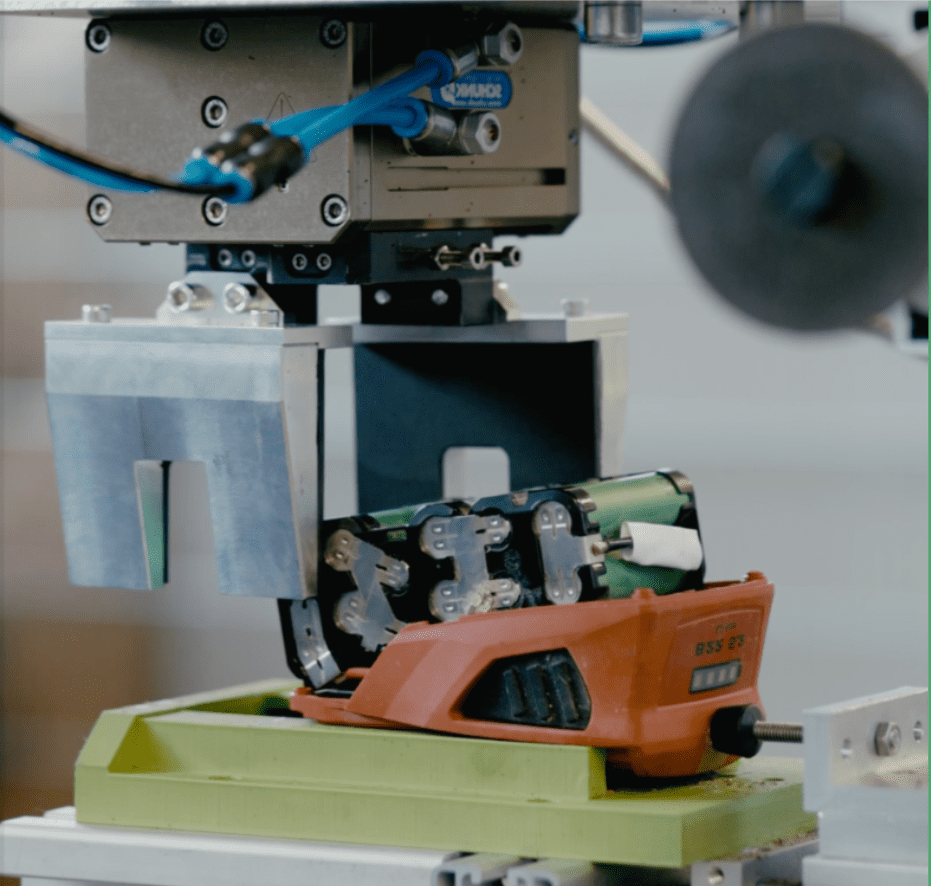

At the heart of Circu Li-ion’s mission is the salvation of usable battery cells, preventing them from being relegated to the oblivion of shredders. Their ingenious machine employs artificial intelligence and an ever-growing “battery library” to visually identify batteries based on their appearance. Furthermore, it effectively separates these valuable cells from other materials, such as plastic housing and PCB boards, while meticulously assessing the cells’ health status.

The destiny of these batteries is determined by their condition. Cells in pristine condition find a second life in the realm of mobility, while those with a less-than-perfect health report may be repurposed to store renewable energy. As for the cells that don’t make the cut, they embark on a journey towards a recycling facility.

Traditionally, recyclers resort to shredding batteries into a homogenous mass and then recovering precious metals through smelting or leaching. Unfortunately, this process results in a myriad of components being irrevocably mixed together and subsequently lost. Antoine Welter emphasizes, “There’s a lot of valuable materials that we can take away that don’t need to land in a shredder.” According to Circu Li-ion’s claims, “more than eight out of ten cells in an end-of-life battery are actually not end-of-life.”

When questioned about the precise methodology behind the machine’s ability to gauge battery health, Welter remained discreet. “We collect more than 25 data points per cell through Electrochemical Impedance Spectroscopy (EIS) testing,” he revealed. “Based on those data points, we can determine, with a remarkable accuracy of 1.2%, how healthy the cell still is.” Drawing an intriguing analogy, he likened testing an old cell to interpreting the rings of a tree, where distinct patterns reveal the cell’s vitality.

Circu Li-ion operates under a business model that charges both manufacturers and recyclers for the utilization of their cutting-edge machines and software. Additionally, the company runs a state-of-the-art facility in Karlsruhe, Germany, dedicated to the disassembly of batteries.

In their previous professional lives, Antoine Welter served as a B2B investor and consultant, while co-founder and CTO Xavier Kohll played a pivotal role in the development of a “soft total artificial heart” at ETH Zurich, a renowned Swiss research university.

Recently, Circu Li-ion secured a significant boost in funding, approximately $4.8 million (€4.5 million) in equity financing led by BonVenture, on top of around $4.2 million (€4 million) in earlier grants from the European Innovation Council Accelerator and other sources. This combined investment of approximately $9 million is poised to propel the startup towards scaling its machine-as-a-service business model and establishing the “world’s largest” repository of battery recycling data.

Circu Li-ion’s machine separates battery cells from plastic housing and other materials, such as PVC boards. Source: Circu Li-ion

Conclusion:

Circu Li-ion’s innovative upcycling machine promises to revolutionize battery recycling by efficiently salvaging usable cells, reducing waste, and enhancing sustainability in the market. Their recent funding success positions them well for scaling their services and building a comprehensive battery recycling data repository, reinforcing their impact on the industry.