TL;DR:

- Northvolt, led by ex-Apple AI scientist Siddharth Khullar, is utilizing AI to enhance electric vehicle (EV) battery technology.

- Khullar’s team is implementing machine learning and AI-driven solutions to boost manufacturing processes and testing capabilities.

- The application of AI in chemistry, cell design, and manufacturing is being explored.

- AI is also being used to replace manual inspections, with thousands of inspection points in Northvolt’s main factory.

- Northvolt, Europe’s primary battery maker, is expanding production in Sweden and plans to establish factories in Germany and Canada.

- The company has raised over $9 billion in equity and debt, with orders exceeding $55 billion from leading automakers.

Main AI News:

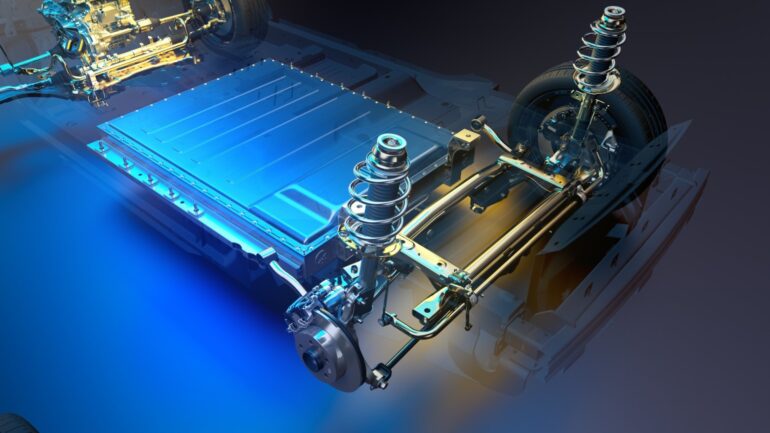

In the race to advance electric-vehicle battery technologies, Northvolt AB is leveraging artificial intelligence (AI) to gain a competitive edge. Spearheading this transformation is Siddharth Khullar, a former AI researcher at Apple Inc., who has assembled a team of machine learning experts at Northvolt. Their mission is to expedite the development and manufacturing processes of the Swedish battery manufacturer, potentially doubling the volume of testing in specific areas.

Operating from Northvolt’s primary facility in Skellefteå, situated just below the Arctic Circle, Khullar’s team has introduced machine learning and AI-driven sensors and software to enhance production and testing. Their current focus is on investigating how AI can accelerate research and development at the Northvolt Labs facility in Västerås.

Khullar stated in an interview, “We think in some areas we would be able to save up to 50% of latency. That would mean being able to do twice the number of experiments with the same number of people.”

The race to commercialize next-generation battery technologies that power electric vehicles more affordably and efficiently has battery manufacturers vying for supremacy. AI offers the potential to unlock new frontiers in battery chemistry and design. While machine learning is relatively uncharted territory in battery research, the data-intensive and intricate nature of the industry makes it an ideal match.

AI is being applied across a spectrum of battery-related domains, including chemistry, cell design, and manufacturing. The team is also exploring how machine learning can replace manual inspections, with Northvolt’s main factory alone boasting approximately 4,000 inspection points.

Khullar emphasized, “AI is about returning time to our people, so they can do more,” noting that the vast amount of data generated in battery production is beyond the capacity of human workers to manage.

Northvolt, Europe’s sole major homegrown battery manufacturer, is scaling up production in Sweden and has ambitious plans to establish factories in Germany and Canada. The company has already secured over $9 billion in equity and debt, underpinned by orders exceeding $55 billion from prominent automotive clients, including BMW, Volvo Car, Polestar, and Volkswagen.

During his tenure of more than six years at Apple, Khullar contributed to features for the Apple Watch and engaged in research projects related to sleep tracking and autonomous driving. In just over a year since joining Northvolt, his team has expanded to 18 members and continues to grow.

Khullar concluded, “AI won’t be able to replace 10 years of working on a specific process in the line. But we can assist them with a lot of knowledge search, summarization, preparation of content, analyzing a ton of numbers, and showing them patterns to make better decisions.“

Conclusion:

Northvolt’s strategic embrace of AI and machine learning technologies in battery production signifies a significant leap forward in efficiency and innovation. With the potential to double testing capabilities and streamline various production aspects, Northvolt is poised to lead the market in advancing electric vehicle battery technologies. This approach not only enhances their competitiveness but also serves as a testament to the transformative power of AI in the manufacturing sector, setting a benchmark for others in the industry to follow suit.