TL;DR:

- Bioprinting technology enables complex 3D shapes, standardization, and quality control.

- AI brings real-time diagnostics and ensures the high quality and uniformity of end products.

- Organoids offer a wide range of research and practical applications, from simulating organ development to predicting therapeutic agents.

- Bioprinting and AI address the challenge of standardizing production and overcoming passive transport limitations.

- Extrusion bioprinting offers high-resolution and automated manufacturing.

- The future of organ manufacturing through bioprinting and AI holds great promise for disease modeling and drug testing.

- Bioprinting and AI are set to revolutionize organoid production by standardizing production, monitoring and controlling quality, and providing real-time diagnostics.

Main AI News:

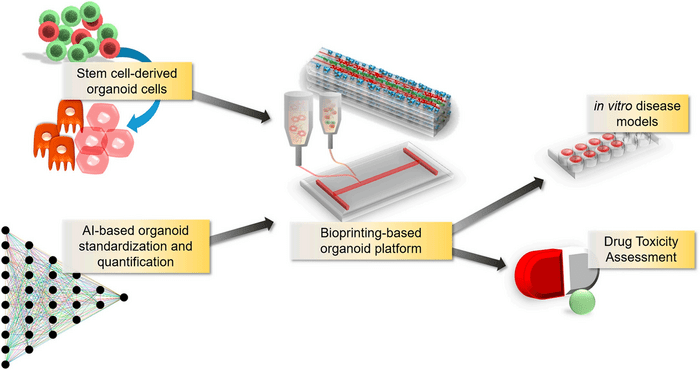

The manufacturing of organoids has received a major boost with the integration of bioprinting technology and artificial intelligence. Bioprinting technology enables the creation of complex biological 3D shapes and structures, as well as standardization and quality control during production. The addition of artificial intelligence brings even greater benefits, allowing for real-time diagnostics of organoids and ensuring that the end product is of high quality and uniformity.

Professor Hyungseok Lee, a renowned expert in the field of mechanical and biomedical engineering, recently spoke about the future of organoid manufacturing at the Cyborg and Bionic Systems conference. He highlighted the potential of bioprinting and AI to revolutionize the organoid manufacturing process and bring about a new era of research and innovation.

Organoids, with their ability to self-organize and assemble, offer a wide range of research and practical applications. They can be used to simulate human organ development, replicate human pathology for research purposes, and even serve as “stand-ins” for clinical patients to predict the best therapeutic agents. With the power of bioprinting and AI, the possibilities are endless, and the future of organoid manufacturing looks bright and promising.

In the field of organoid production, bioprinting and AI are proving to be game-changers. The challenge of standardizing the production of organoids, with their potential for disease modeling and personalized therapy predictions, has long been a hindrance. But with bioprinting technology, the creation and maintenance of complex biological structures can be standardized and quality-controlled, while AI provides real-time diagnostics and feedback to further optimize the process.

Extrusion bioprinting, in particular, offers the potential for high-resolution and automated organoid manufacturing, with the ability to fabricate vascularized organoids and minimize passive transport limitations. Meanwhile, AI ensures the quality of the final product by monitoring the bioprinting process in real time and providing feedback for fine-tuning.

The future of organ manufacturing through bioprinting and AI holds great promise for the modeling of complex diseases and the testing of new drugs. With its ability to standardize production, monitor and control quality, and provide real-time diagnostics, bioprinting, and AI are set to revolutionize the field of organoid production.

Standardized organoid produced by bioprinting combined with artificial intelligence promises to replace experimental animals as disease models and for drug screening. Source: the American Association for the Advancement of Science

Conlcusion:

The integration of bioprinting technology and artificial intelligence has the potential to greatly impact the market for organoid manufacturing. The benefits of bioprinting, including complex 3D shapes, standardization, and quality control, are further amplified by the addition of AI. This technology provides real-time diagnostics and ensures high-quality, uniform end products.

With its ability to standardize production, monitor and control quality, and provide real-time diagnostics, bioprinting, and AI are poised to revolutionize the field of organoid production and bring about a new era of research and innovation. The market for organoid manufacturing is expected to grow significantly as a result of these advancements, and companies that invest in this technology are likely to reap the benefits in the form of increased demand for their products and services.